Brief Intro

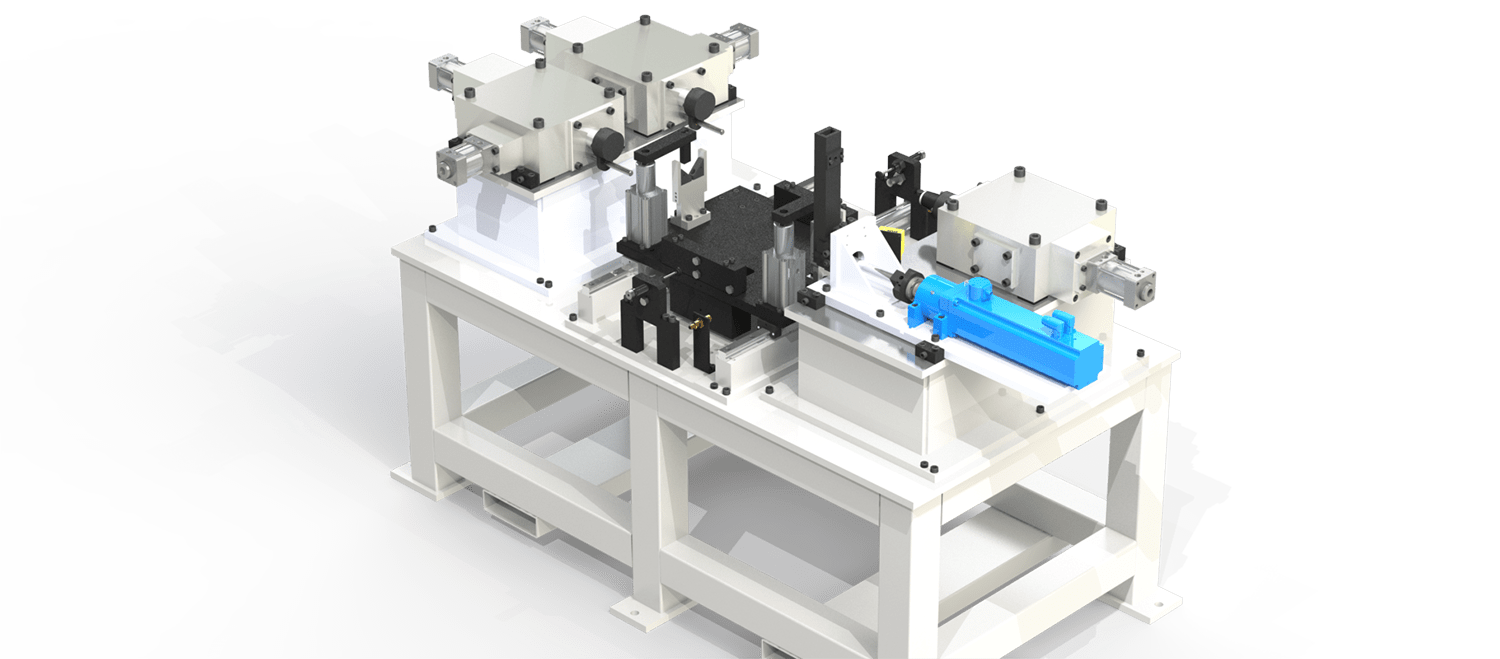

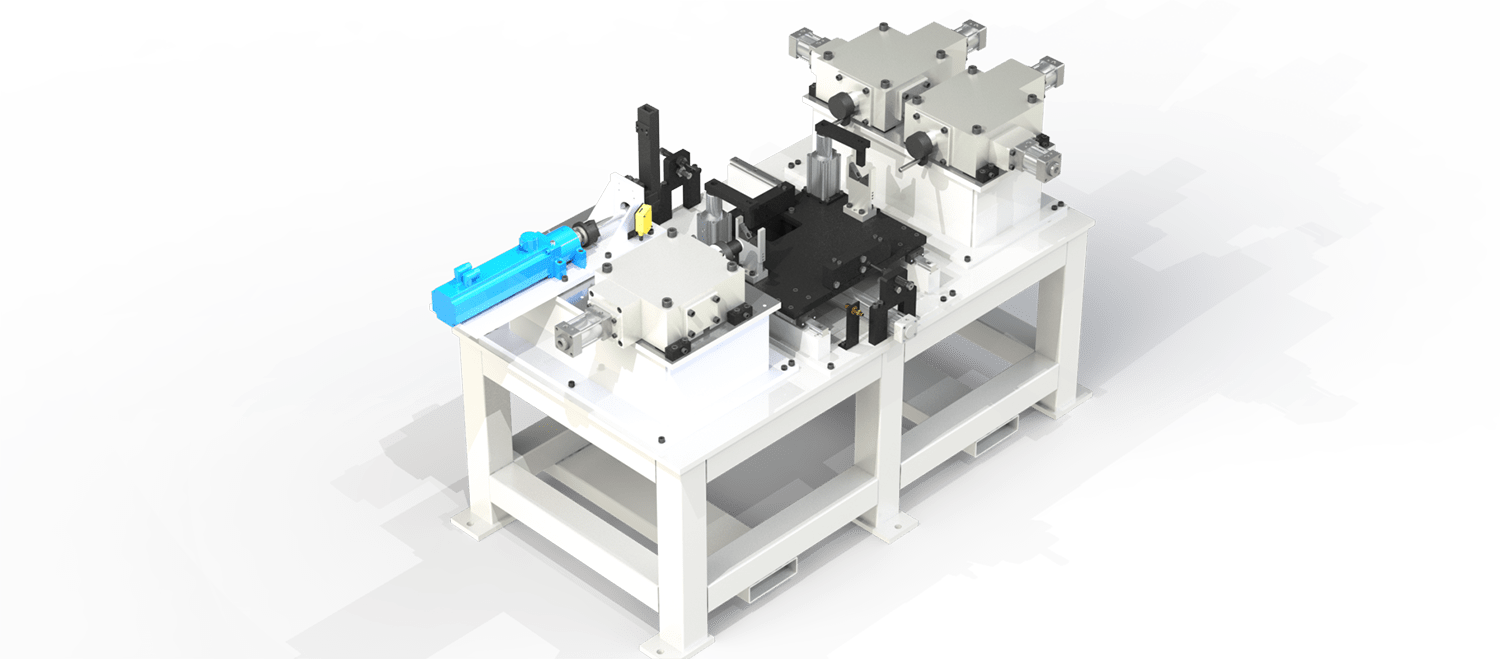

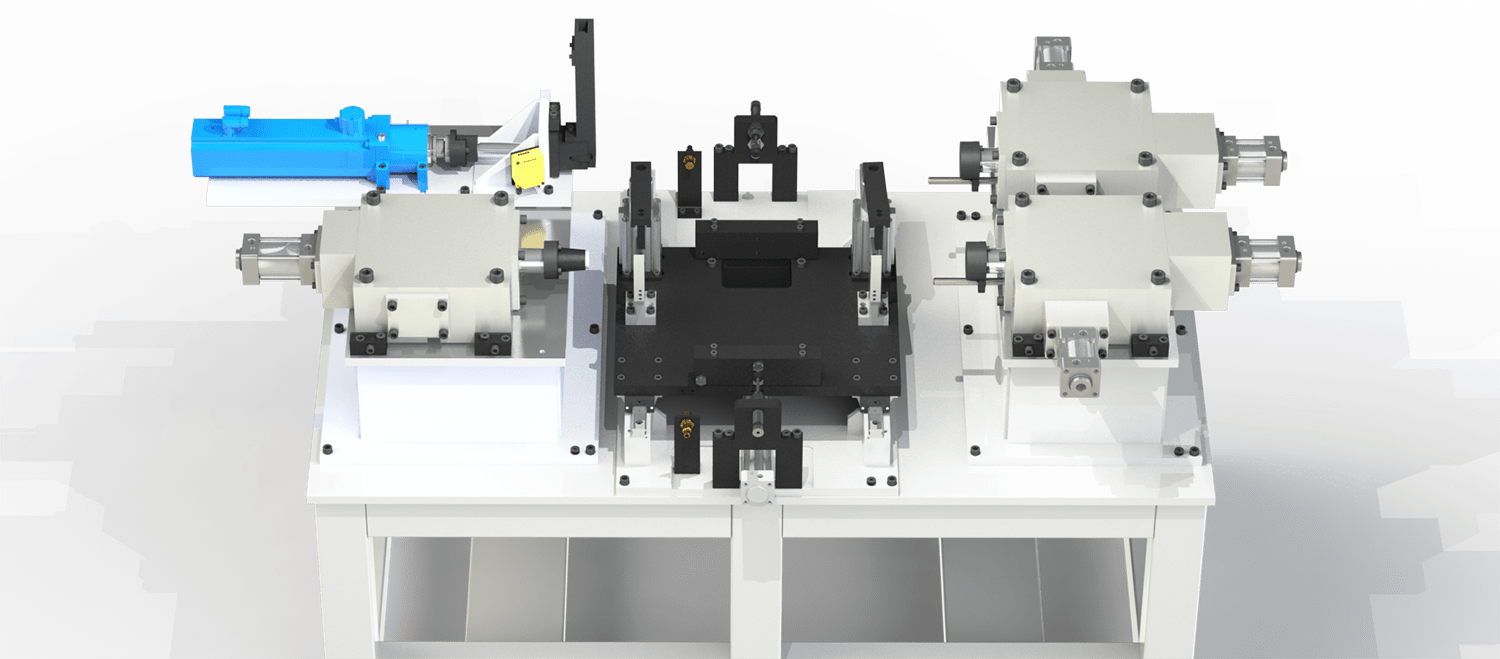

All in one: A solution that precision-presses a sealing plug, then performs a calibrated leak test. How’s that for quality peace of mind? This system is custom tailored to your press application, so any deviation from the standard press curve alerts the operator. As an additional safety-guard, each part is then leak tested to ensure 100% compliance. No more guess work with another winner solution by FLT.

Technical Details

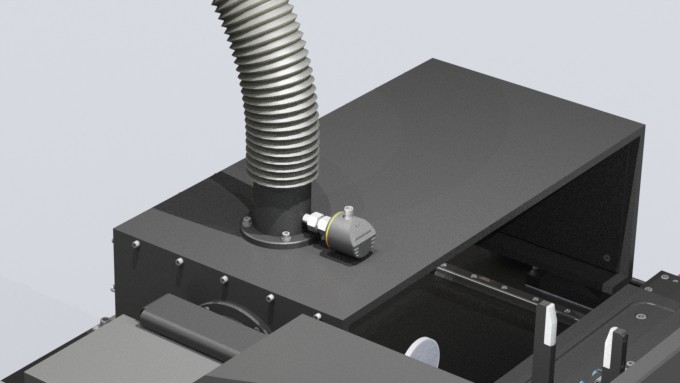

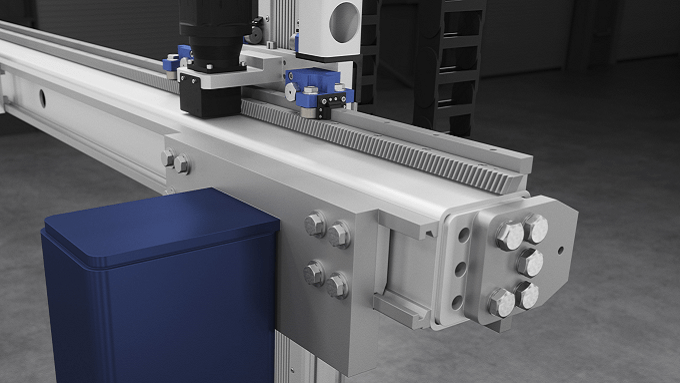

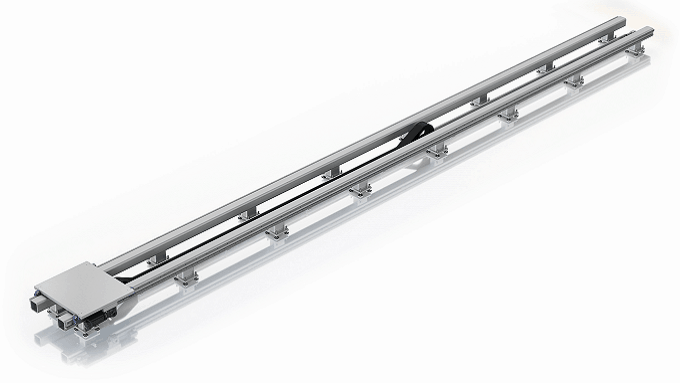

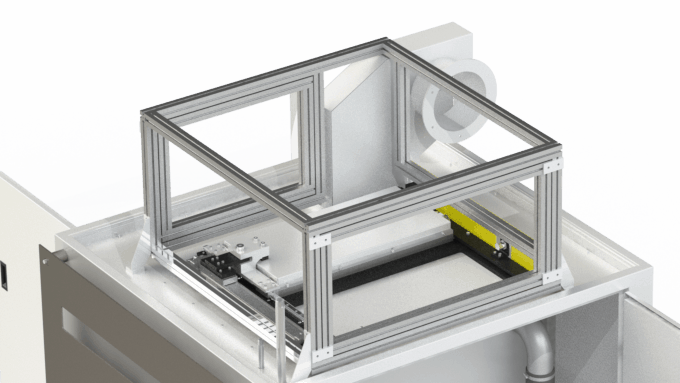

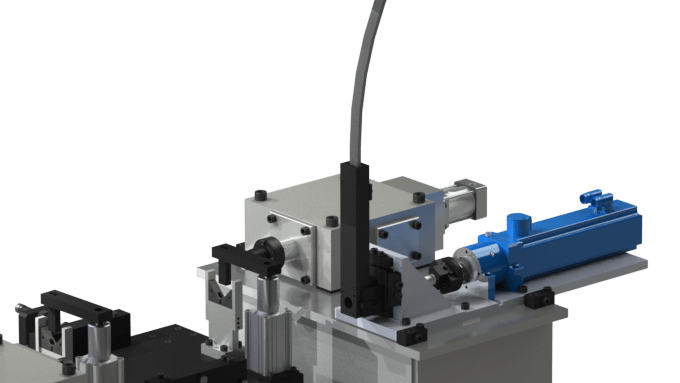

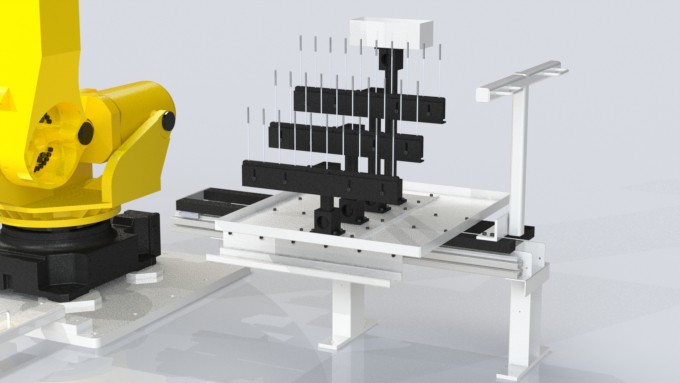

Automated Feeder System

- This automated solution feeds cup plugs to the assembly machine ensuring proper orientation and alignment. Removing the guess work from the machine setup.

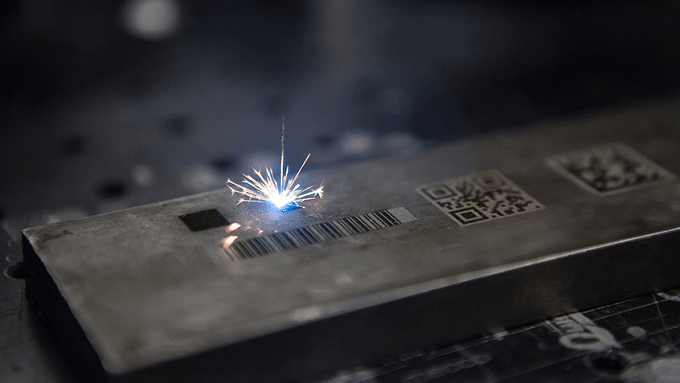

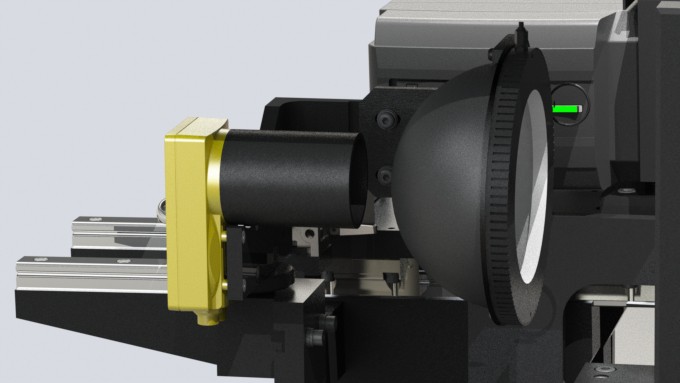

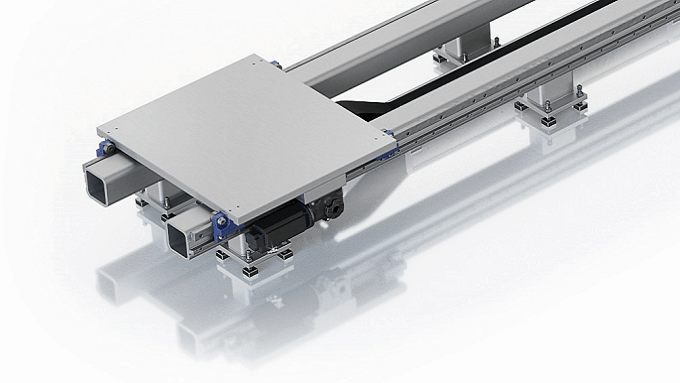

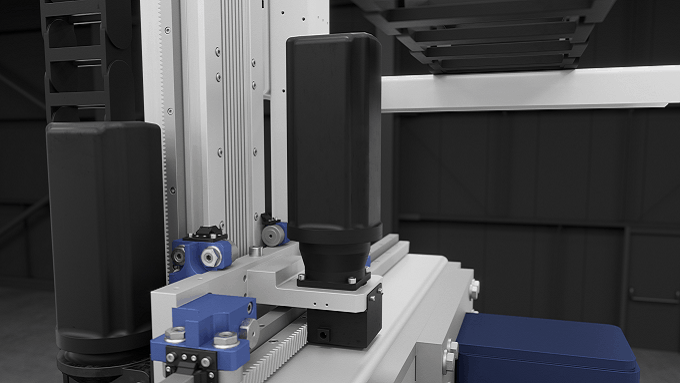

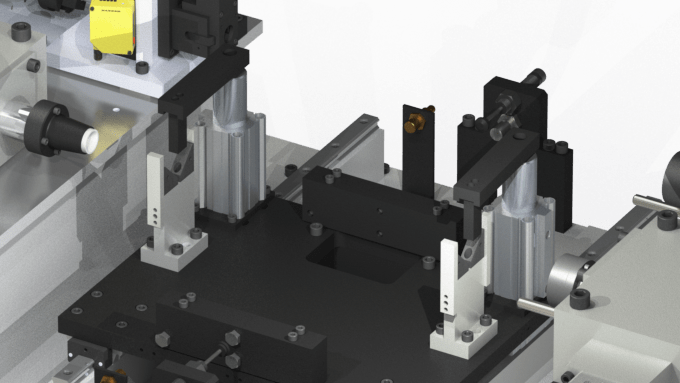

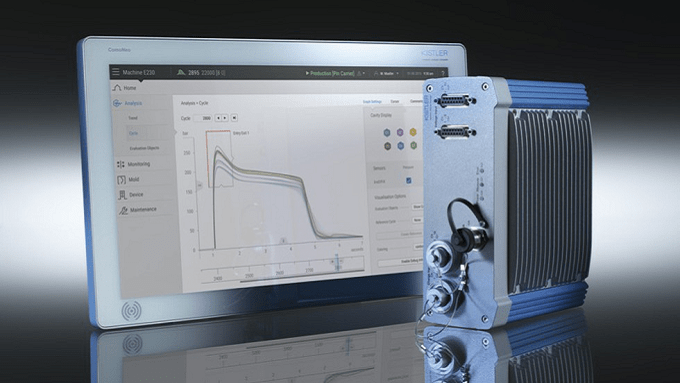

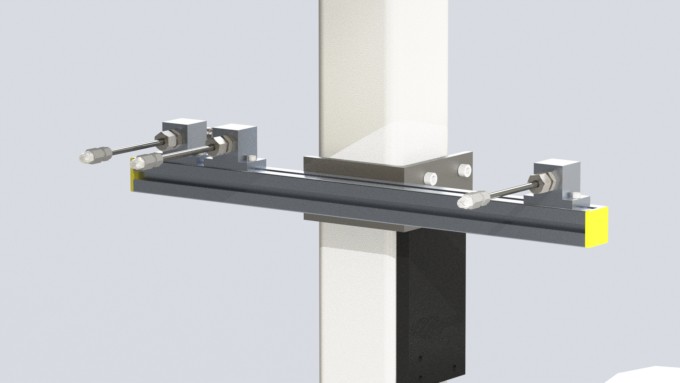

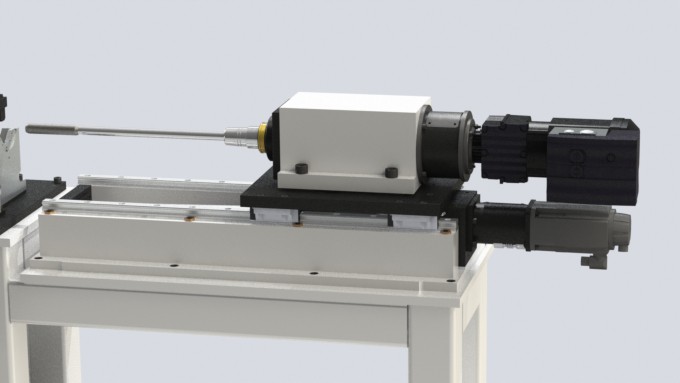

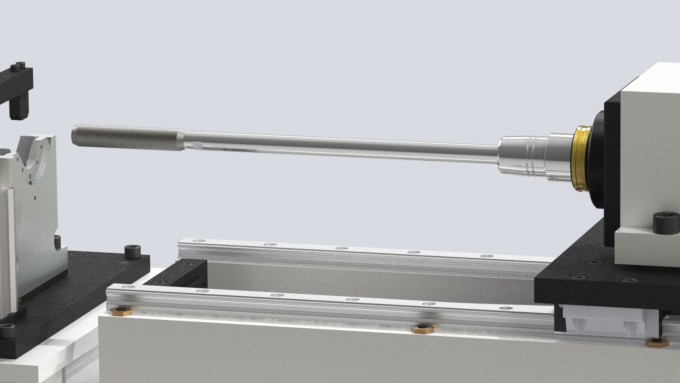

Precision Force and Distance Monitoring

- Press depth and forces are monitored with high accuracy, ensuring a consistent, ensuring compliance with the desired press curve.

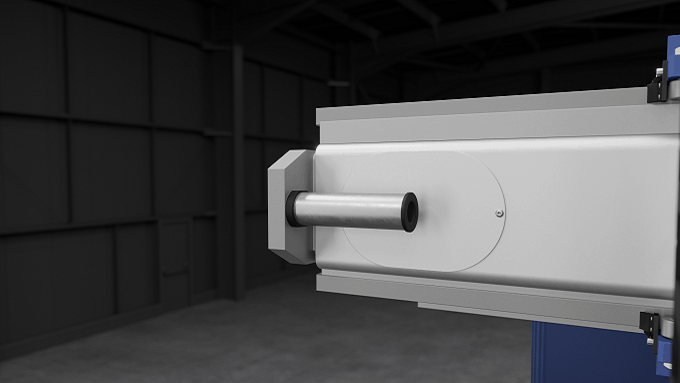

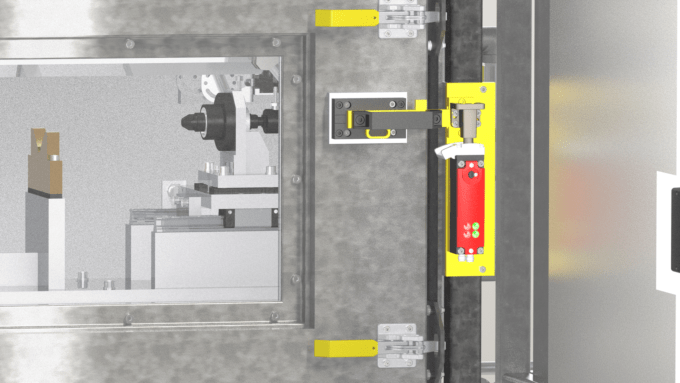

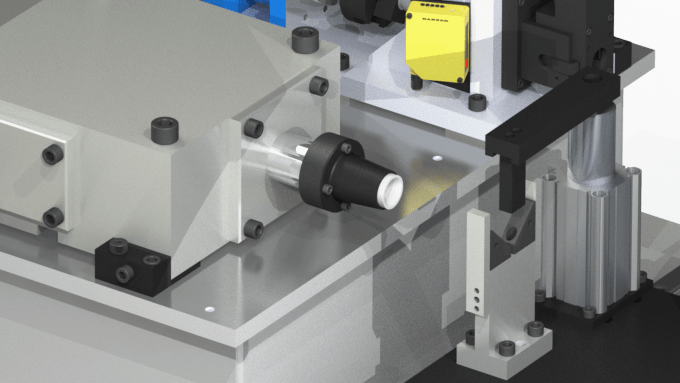

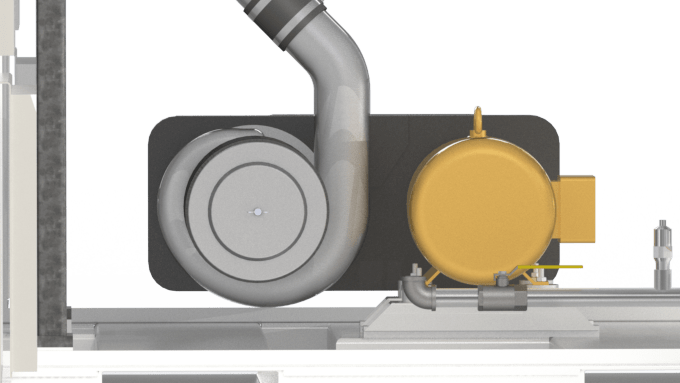

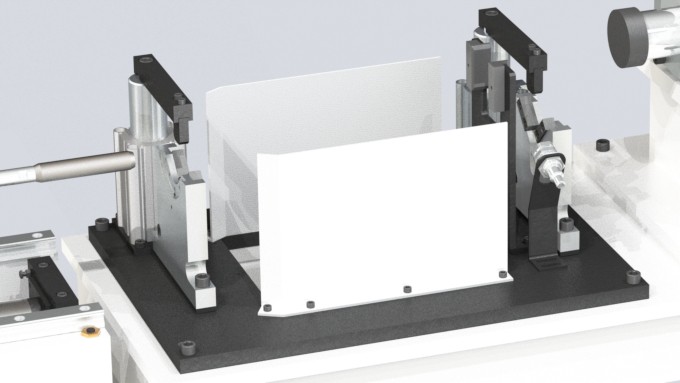

Air Decay Leak Test

- More quality safeguards? Once pressed a leak test seal apparatus uses pressurized air to ensure a strong seal.

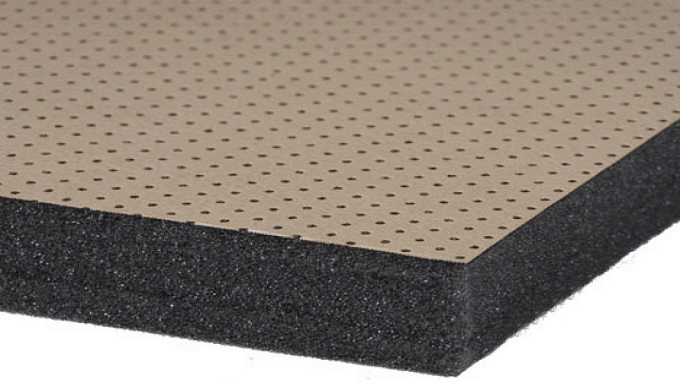

Automated Seal End Of Life Tracking

- Built in to each leak test, the precision press tracks the life of each leak test seal ensuring an accurate test every time.

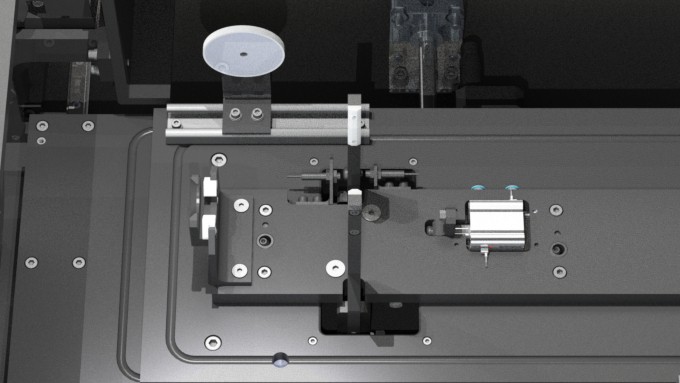

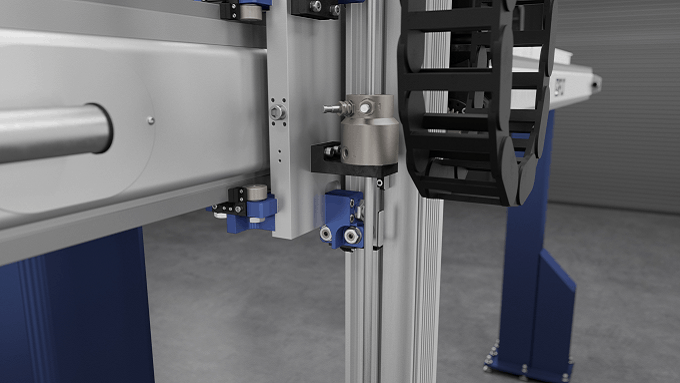

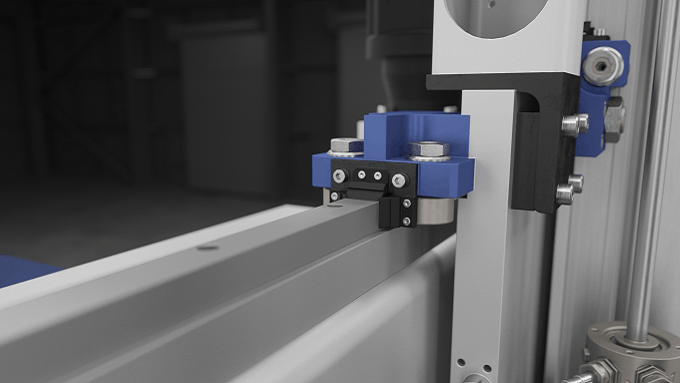

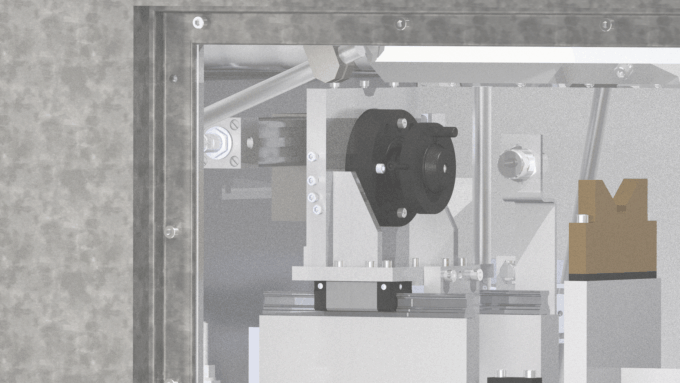

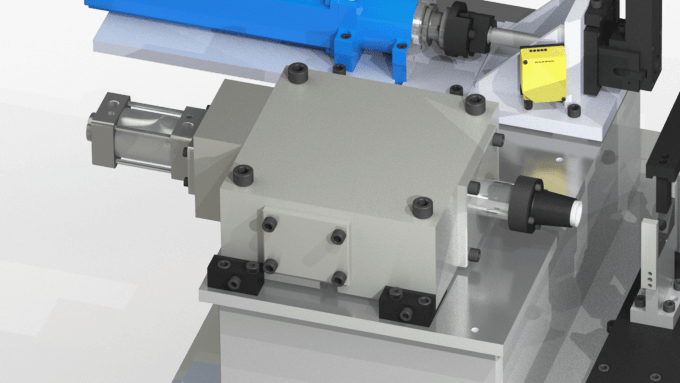

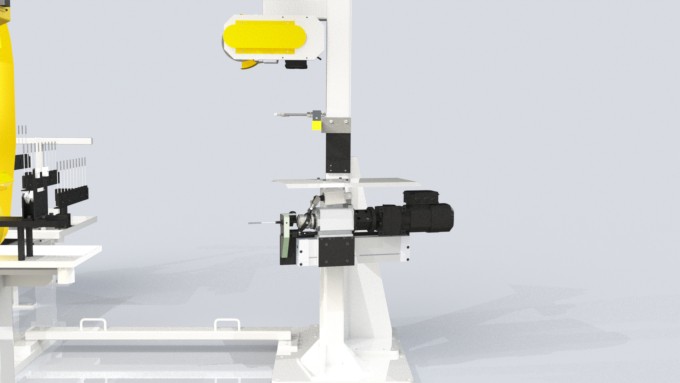

Swivel Clamp Positioning

- Swivel clamps are used to properly locate the part to ensure consistent positioning and stability during the press.

Help and Support

Our service team ensures that FLT modules and systems always provide maximum performance. Be it telephone consulting on short notice, rapid replacement parts supply, or installation sets on site, FLT’s service technicians are ready to help with their knowledge, flexibility and reliability.

Integrate

Learn how our solution specialization can help you build a better system.

Maintain

We can help you get the best out of your system for years to come.

Adapt

Solutions that are built with more in mind than meets the eye.

We look forward to your message.

Fibro Laepple Technology Inc. | 33286 Sterling Ponds Blvd. | Sterling Heights, MI, 48312 USA

info@FLT-US.com

1-248-591-4494