03/18/2019

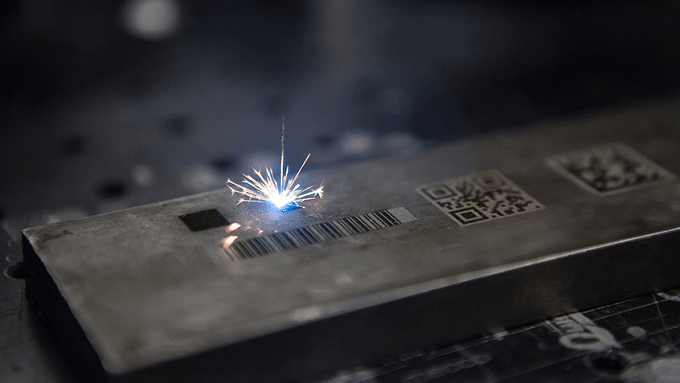

2D Matrix, human readable, even images – custom etch whatever your process requires.

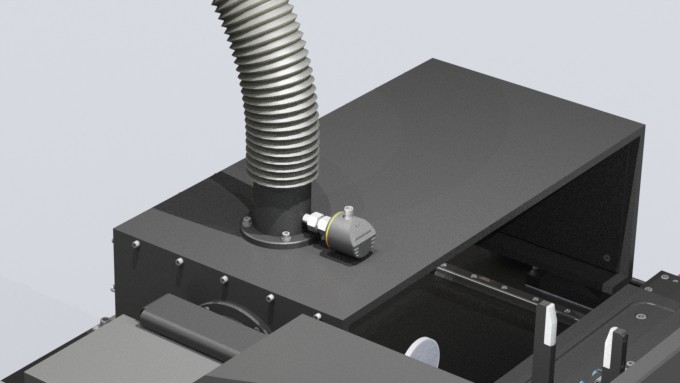

Ensures your environment remains safe by eliminating burn fumes.

Our system comes with full FDA certification, so you’re covered on all ends.

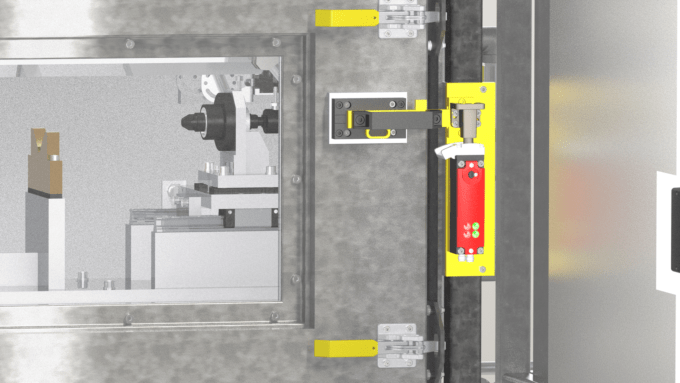

Safety is a big deal. Our light tight enclosures come fully certified to give you peace of mind.

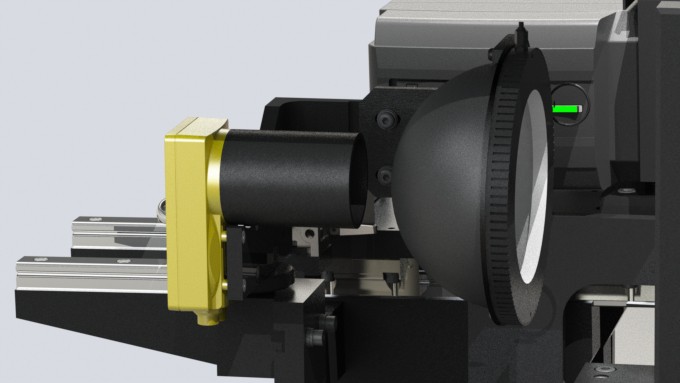

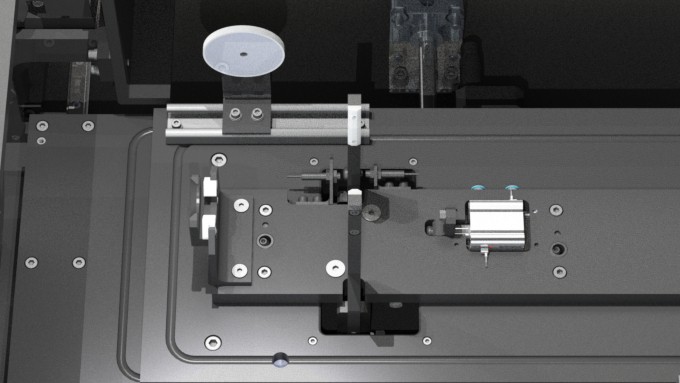

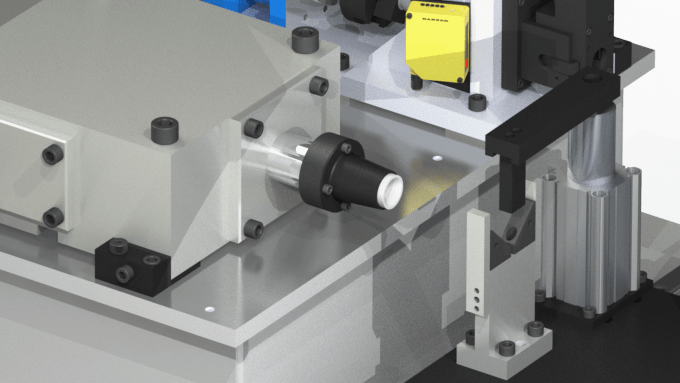

Integrated imaging system to evaluate, grade, and even export images on the fly.

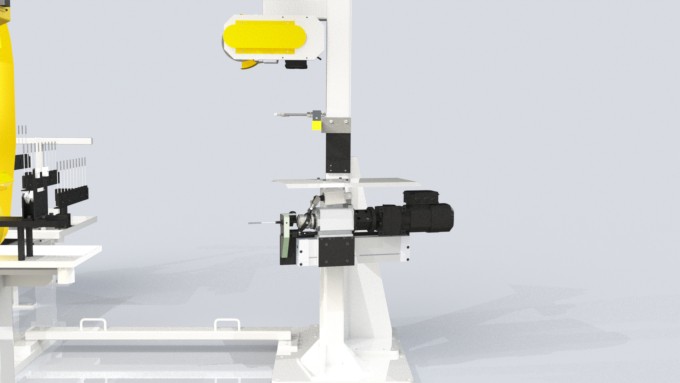

Automatic fixture adjustments to accommodate part type changes without cycle time impact.

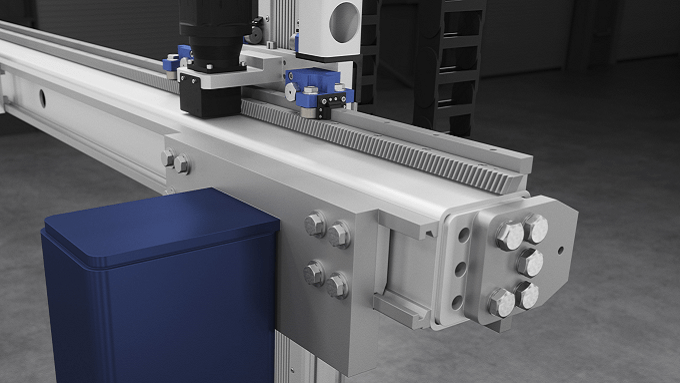

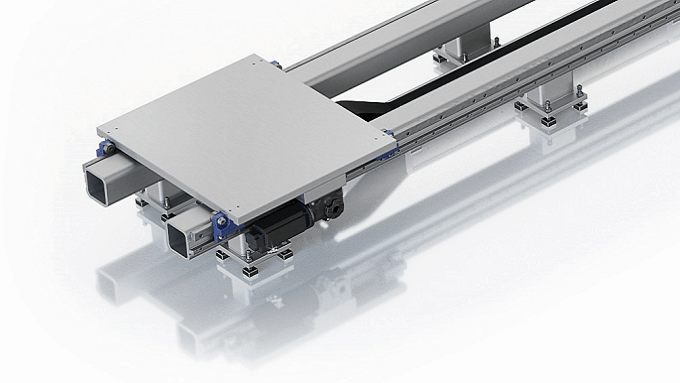

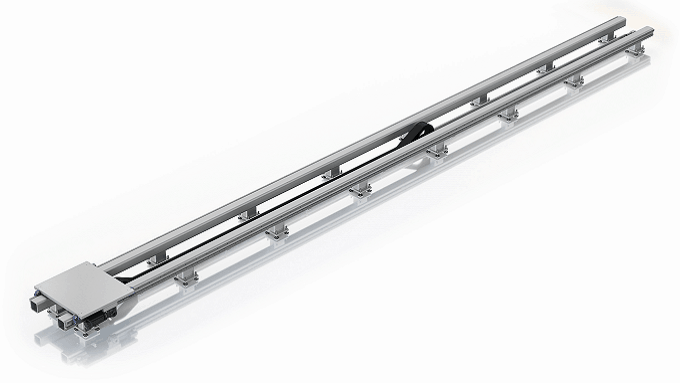

Dovetail guide means that the racks and all attached components can be positioned flexibly.

Dovetail guide means that the racks and all attached components can be positioned flexibly.

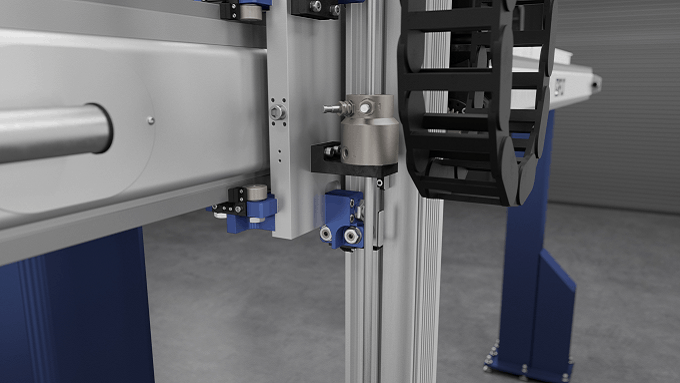

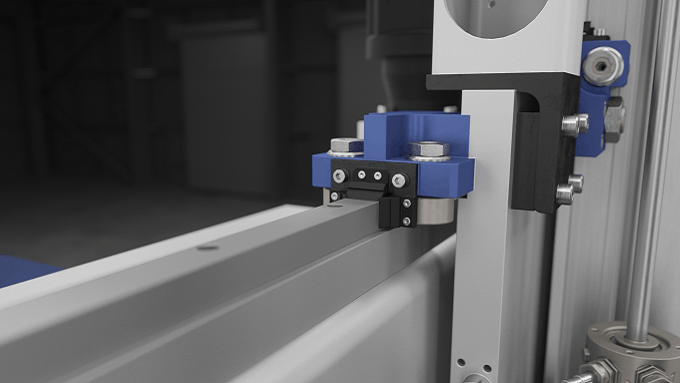

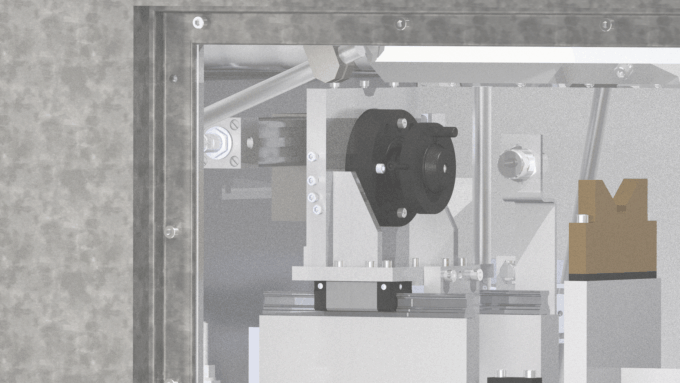

Eccentric rollers for optimum alignment of the vertical axis and the gripper.

Eccentric rollers for optimum alignment of the vertical axis and the gripper.

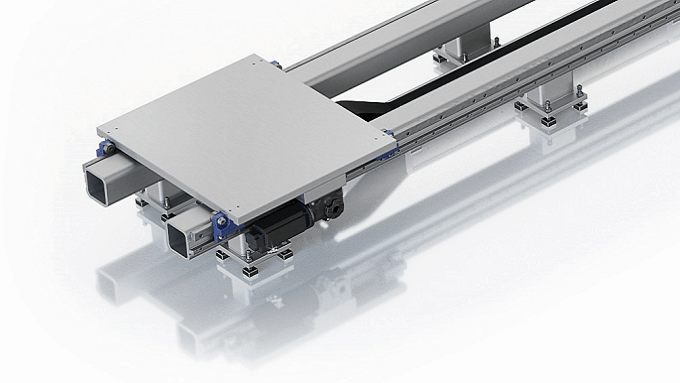

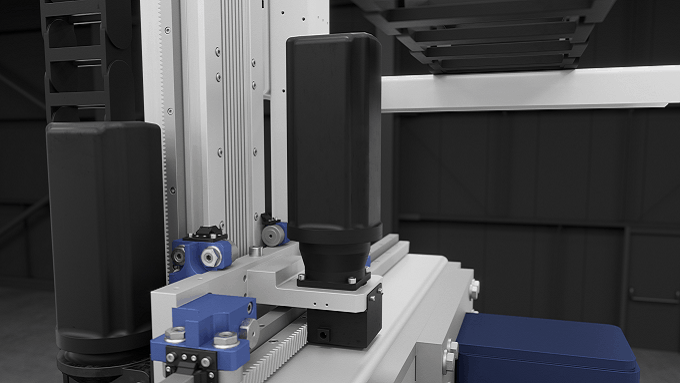

Several parallel Y-axes possible.

Several parallel Y-axes possible.

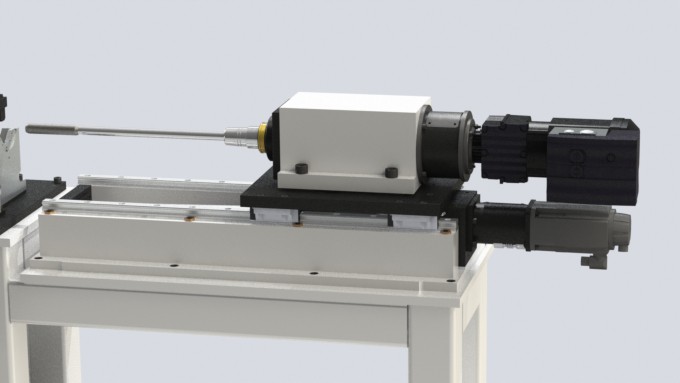

There are countless possible carriage options.

Contact us for more detail.

There are countless possible carriage options. Contact us for more detail.

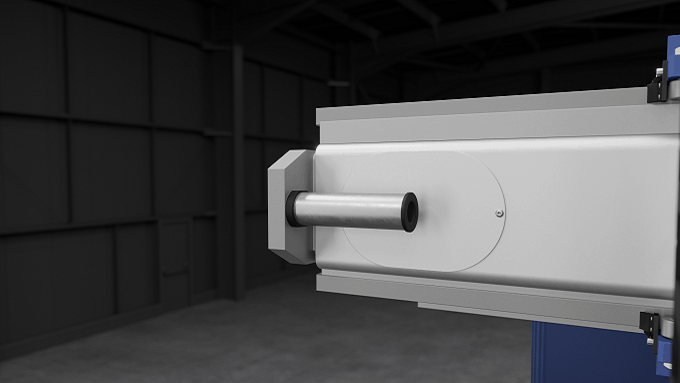

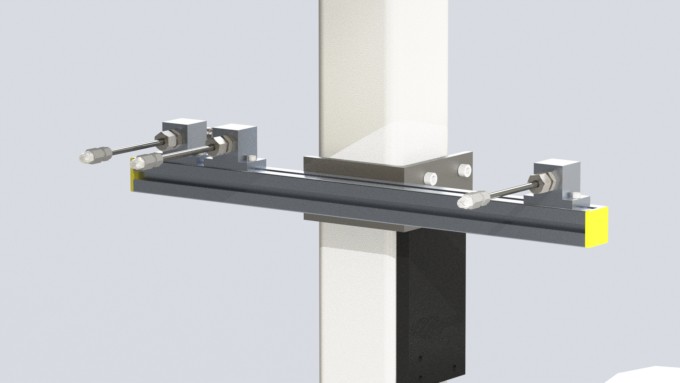

The hardened guide rails provide extreme durability and low wear, while the triple roller system supports optimum power transmission.

They are also extremely easy to maintain as replacement is quick and simple.

The hardened guide rails provide extreme durability and low wear, while the triple roller system supports optimum power transmission. They are also extremely easy to maintain as replacement is quick and simple.

The system is very energy efficient due to planetary and bevel gears.

Interface allowing custom gear selection.

The system is very energy efficient due to planetary and bevel gears, as well as an interface allowing custom gear selection.

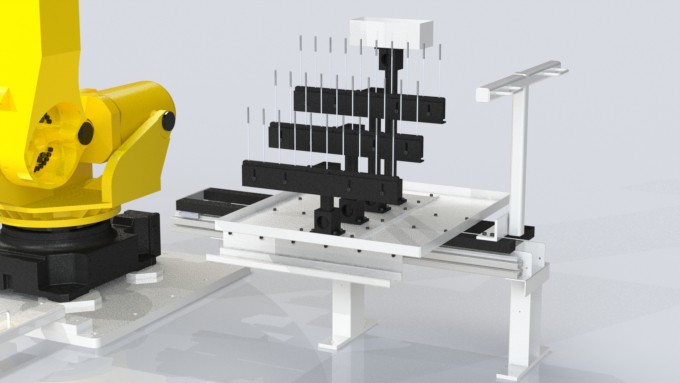

There are numerous attachment options and carriage sizes for robots and fixtures.

Contact us for more detail.

There are numerous attachment options and carriage sizes for robots and fixtures. Contact us for more detail.

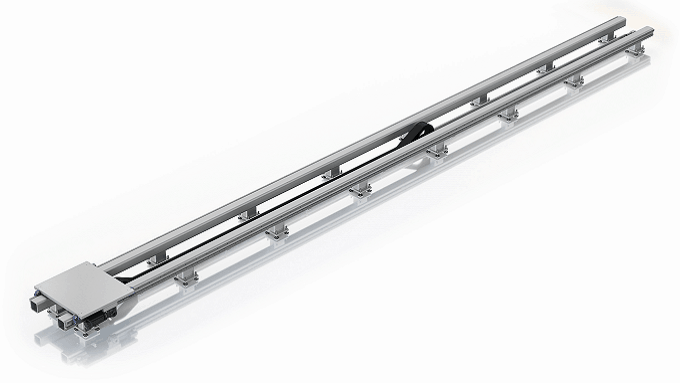

Thanks to the flexible interface at the start and end of the carrier, the horizontal axis can be extended to 100 m, shortened or split.

Thanks to the flexible interface at the start and end of the carrier, the horizontal axis can be extended to 100 m, shortened or split.

In the event of a collision, shock absorber units dissipate energy and protect the system from damage.

In the event of a collision, shock absorber units dissipate energy and protect the system from damage.

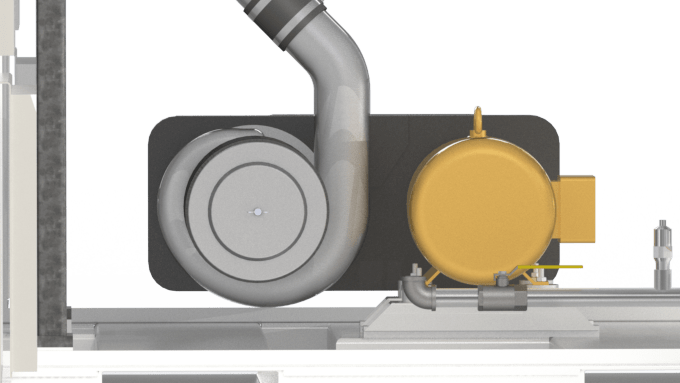

With adjustable rotation speeds and multiple rotations per cycle, this solution ensures thorough cleaning over the entire part.

Quiet too? Yup, this system offers high performance service while minding the safety of your workers.

The plexiglass door is safety interlocked so you can observe the process without any hazard.

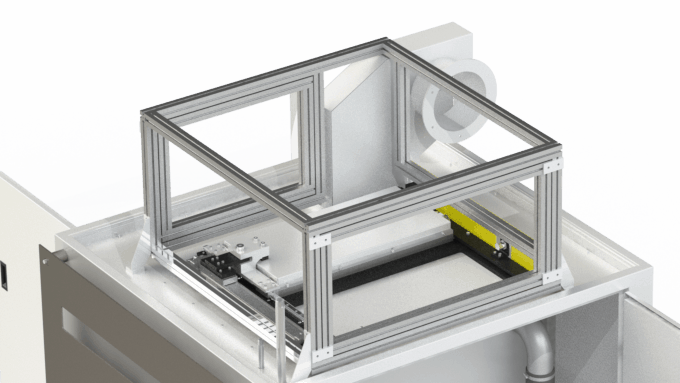

Automated overhead door regulation and lock conditions ensure the washer and dryer machine remains completely enclosed.

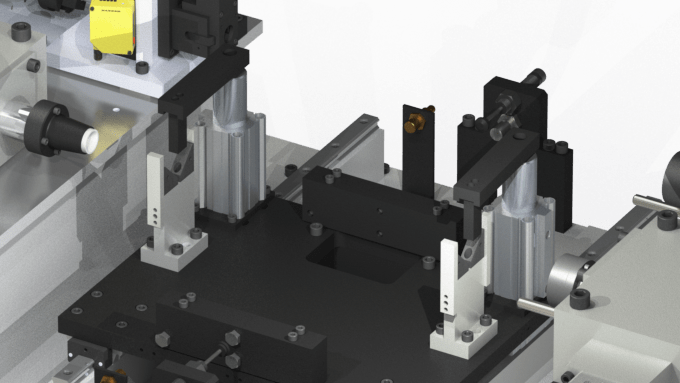

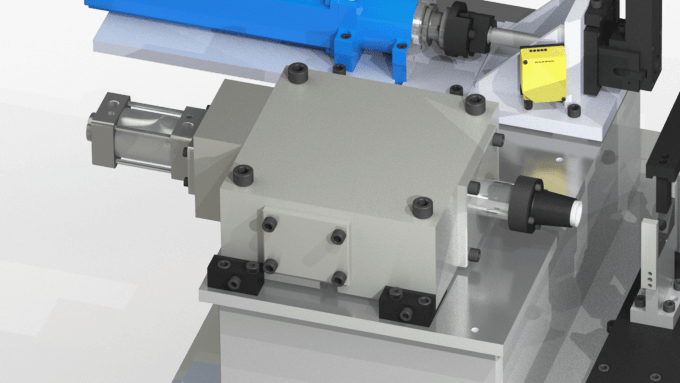

Swivel clamps are used to properly locate the part to ensure consistent positioning and stability during the press.

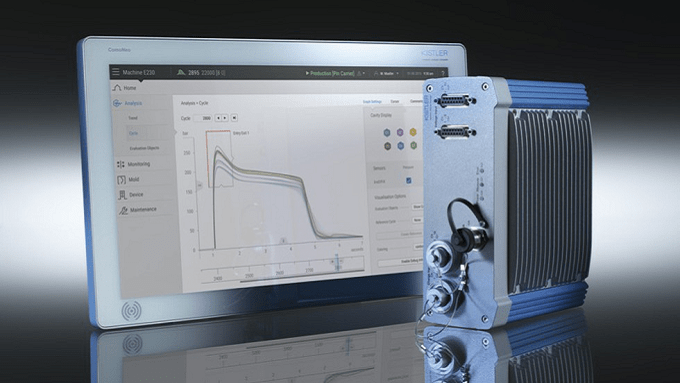

Built in to each leak test, the precision press tracks the life of each leak test seal ensuring an accurate test every time.

More quality safeguards? Once pressed a leak test seal apparatus uses pressurized air to ensure a strong seal.

Press depth and forces are monitored with high accuracy, ensuring a consistent, ensuring compliance with the desired press curve.

This automated solution feeds cup plugs to the assembly machine ensuring proper orientation and alignment. Removing the guess work from the machine setup.

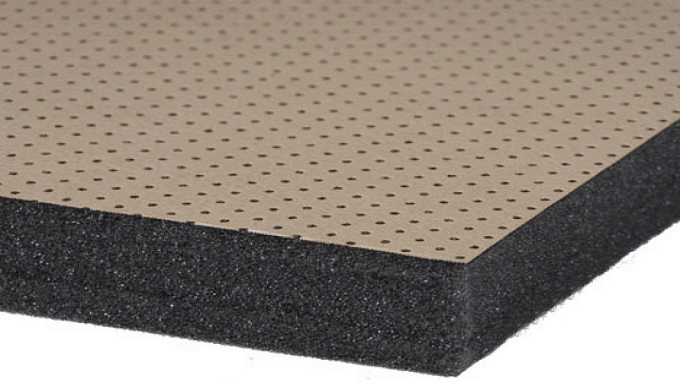

Using modern air knives, high velocity air can be adapted to dry or clean debris from parts in accordance with your production needs.

An automated self-cleaning cycle ensures easy use with minimum downtime for maintenance.

Providing organized tool storage our tool stand can be adapted to your process requirements. Deburr brushes from small to large, this system can meet all your process needs.

Adjustable cycle limits allow the system to automatically change tools, reducing downtime and increasing production rates.

Sensor control is used to ensure the complete processing of the part.

This addition ensures metal chips left from deburring are removed before leaving the cell.

Safety is priority. This system is free of floor trays removing all tripping hazards and keeping your workers protected. A tie bar is provided for alignment purposes, but can be removed once the equipment has been installed.

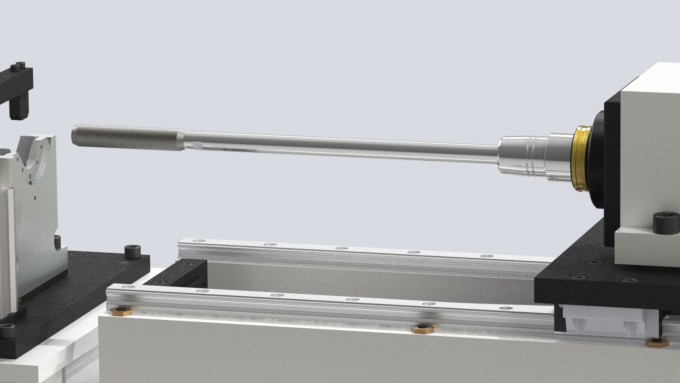

Automated deburring solution – the COFA tool can deburr while both advancing and retracting, adapting to all your process requirements.

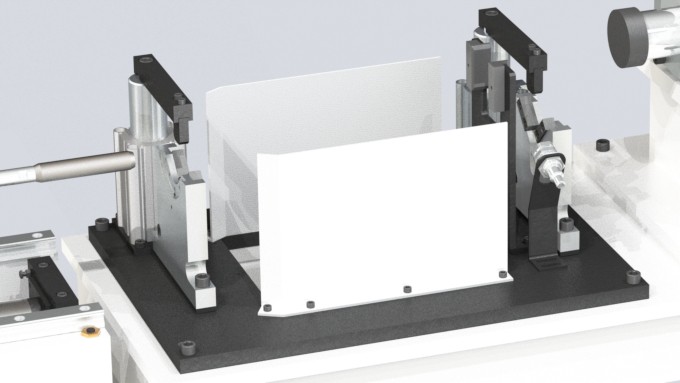

This system adapts to any deburring situation, including uneven and multifaceted surfaces.

Keeping the operations clean, the chip collection system provides a simple and reliable solution with easy removal and replacement.

Using modern teach pendant technology safely entering the cell has never been easier, allowing for precision setups and simple maintenance access.

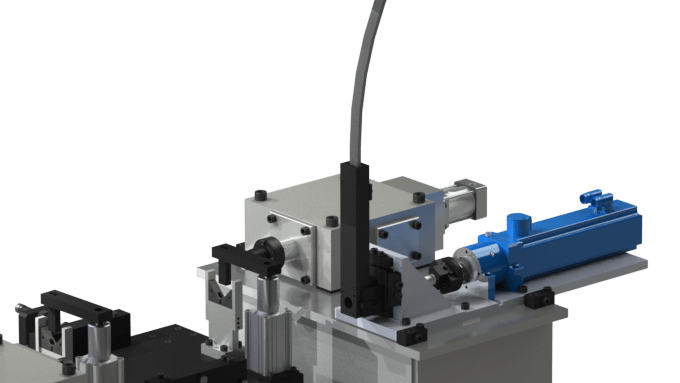

Swivel clamps are used to accurately position the part in order to ensure a consistent and reliable process.

Using modern teach pendant technology this cell allows for easy maintenance access and precision machine setups, while ensuring the safety of your workers.