Gantry systems are not typically thought of as portable equipment. They are large systems, usually permanently anchored to the floor.

Demonstrating its functionality at trade shows is sometimes limited to videos of the equipment and brochures with photos and technical information. Useful, but not the same as seeing one in operation.

With the launch of the new LGR-3 gantry system, FLT decided it was important for people to see some of the precision and speed capabilities in person. It will make its debut at the Automate show in Chicago, April 8-11, 2019. Come see it in operation at booth 7902.

Here is a link to the video:

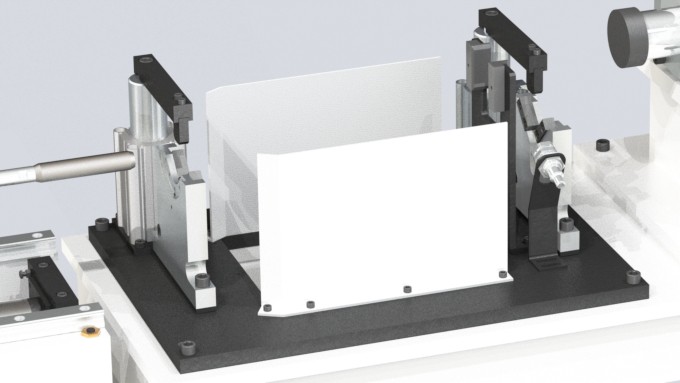

Highlights of the demonstration include:

- A Keyence SR-2000 camera reads the customer’s name badge.

- Customer then selects, on-screen, an item to be engraved.

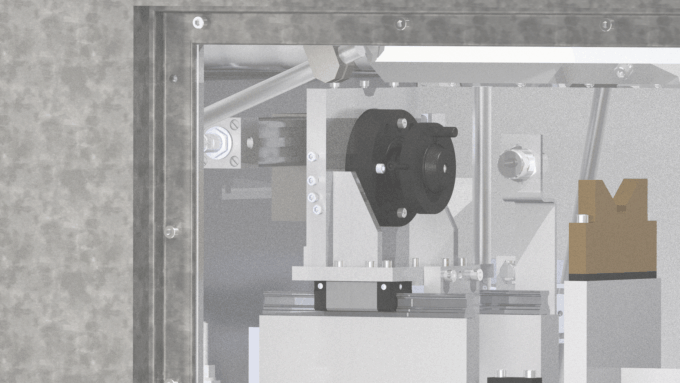

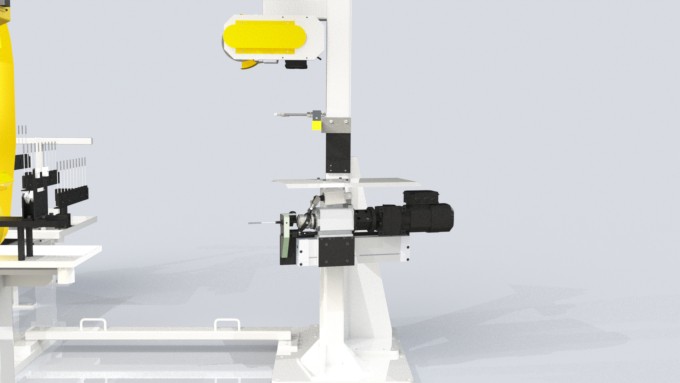

- FLT’s LGR-3 gantry proceeds at 4.5 m/s to pick up the chosen item.

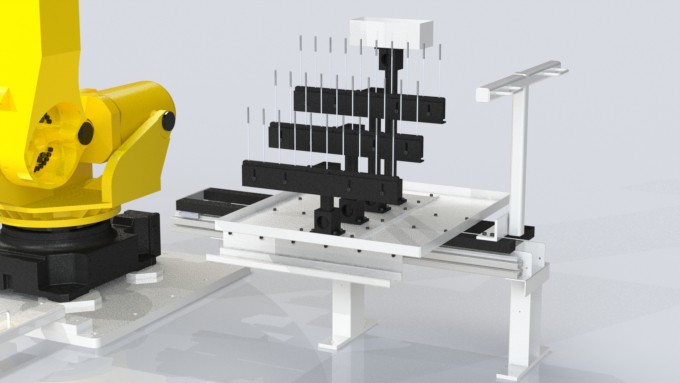

- The LGR-3 hands it off to the Fanuc LR Mate 200iD robot.

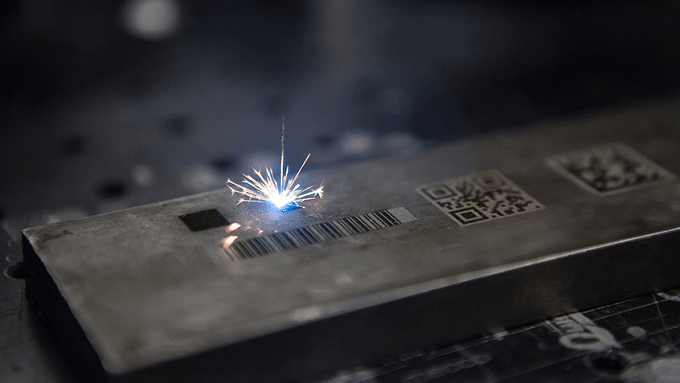

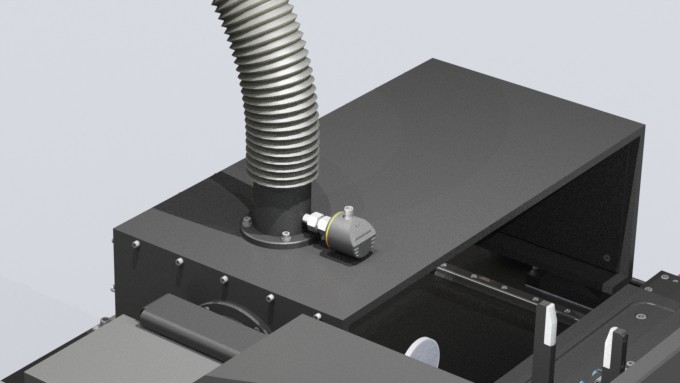

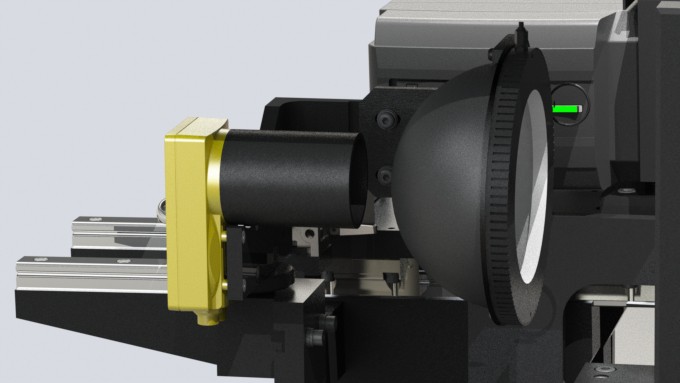

- Robot places item in the Keyence MD-X1000 Hybrid laser for engraving.

- Upon completion, the Fanuc robot retrieves the engraved item and drops it in the chute, delivering it to the customer.

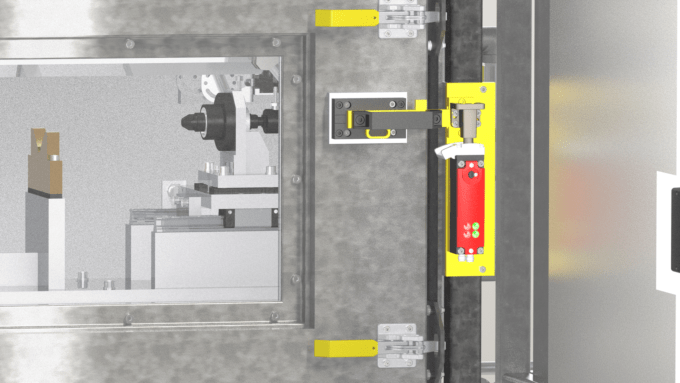

- Hardware controls for all devices are Rockwell Automation software and interfaces.

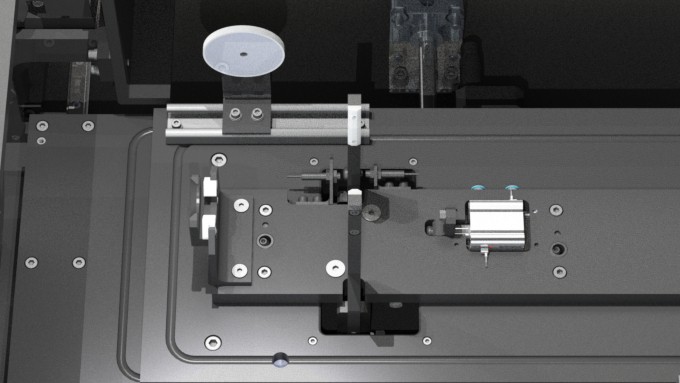

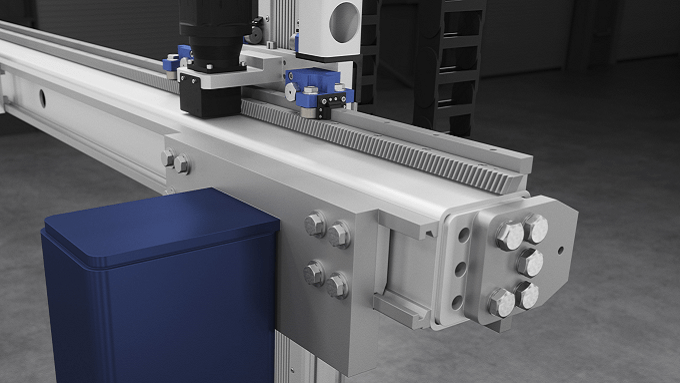

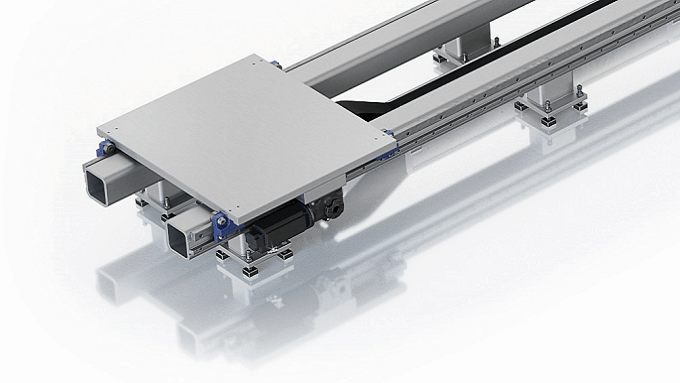

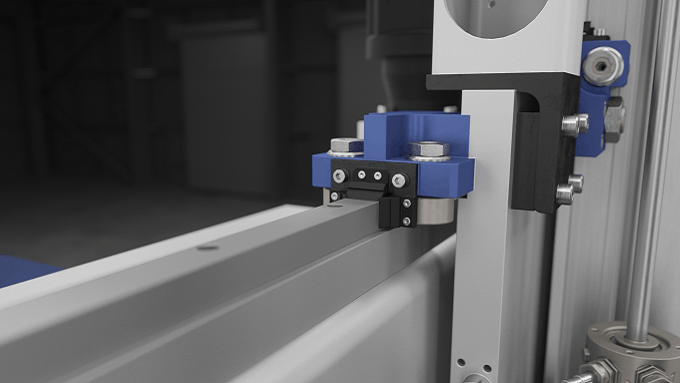

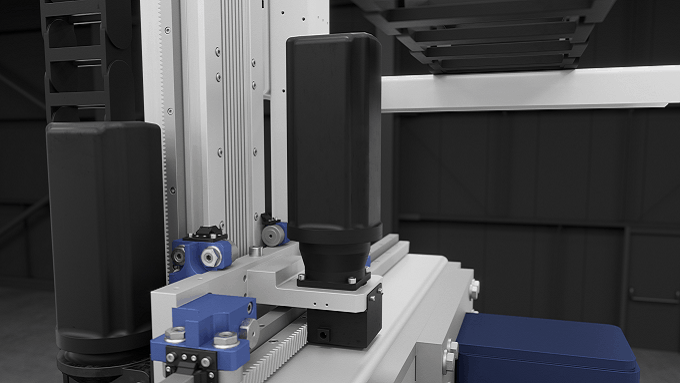

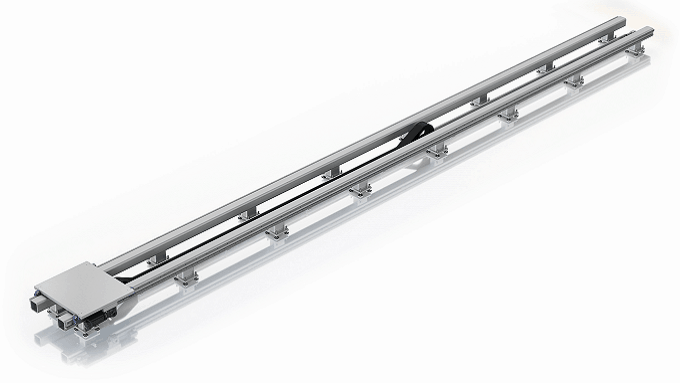

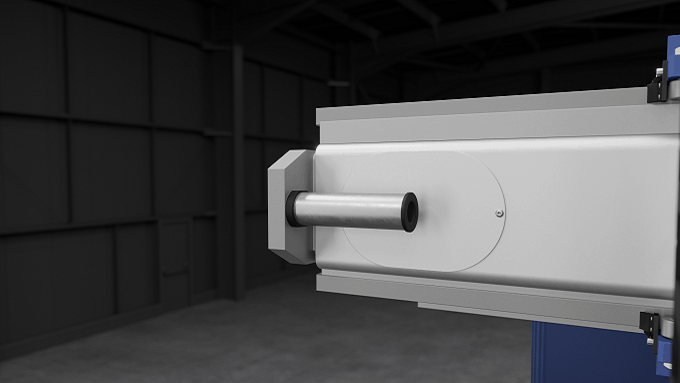

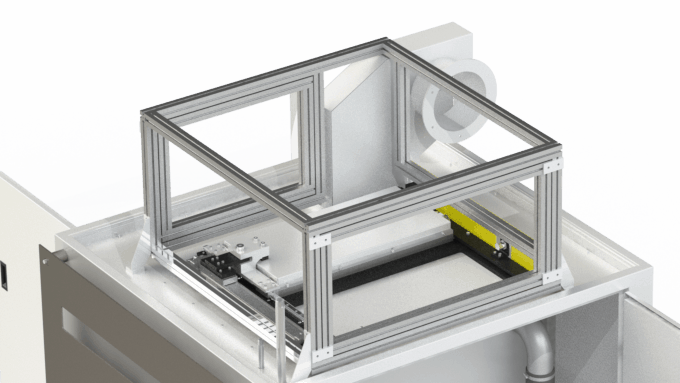

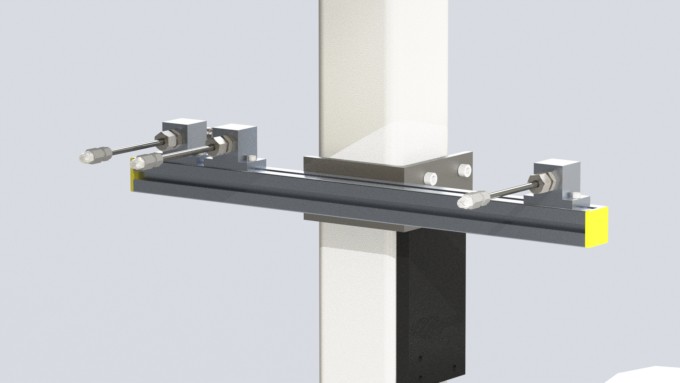

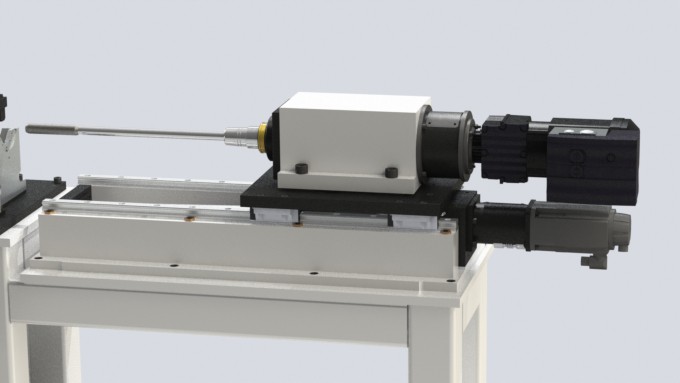

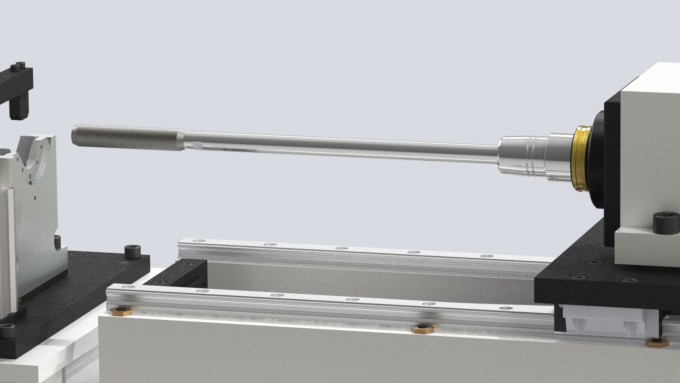

Features of the new LGR-3 linear gantry robot include:

- Payloads up 3000 kg

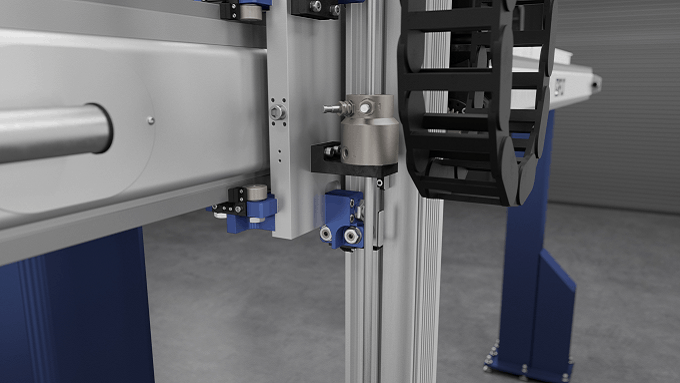

- Horizontal travel can be over 100 m with a vertical stroke up to 3 m.

- Horizontal speed ranges up to 4.5 m/s; acceleration to 6 m/s2.

- Vertical speed ranges up to 2 m/s; acceleration to 4 m/s2.