We love technology – now and since our beginning in 1919! LÄPPLE Group celebrates its 100th anniversary this year. Such an event is a good time to look at the path that got us here, and, how it shapes the future.

In 2019, we are celebrating the knowledge, courage and commitment of all employees who have supported LÄPPLE over the last 100 years. Also, of course, our founder, August Läpple, whose expertise, versatility, adaptability and passion made the company what it is today. These characteristics have become fundamental to our corporate culture.

100 YEARS OF MAXIMUM PRECISION

Our anniversary motto expresses what has distinguished our company for the last century and continues today – Maximum precision.

August Läpple was a toolmaker with great passion for his trade. Putting his considerable skill to work, making high precision products, he soon earned a reputation for quality. Living up to his credo “If you don’t go forward, you’re moving backwards”, he was a technology trailblazer, ever increasing his expertise.

“Precision” continues to be an apt description of what we expect in all of our products, processes, and services, as well as ourselves. Precision, as the criterion for evaluating quality, is what distinguishes LÄPPLE AUTOMOTIVE, FIBRO, FLT and our training company in every area of our business:

- Precision manufactured sheet metal parts.

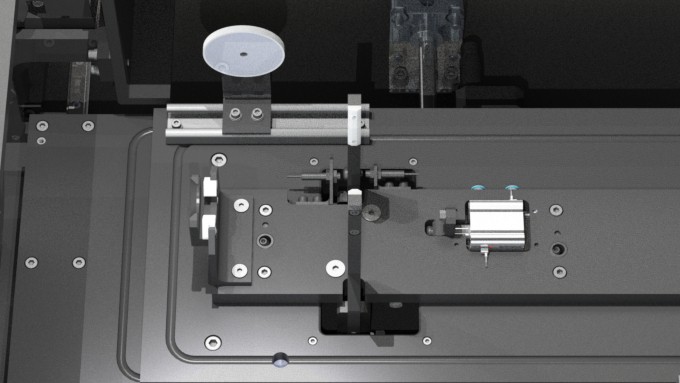

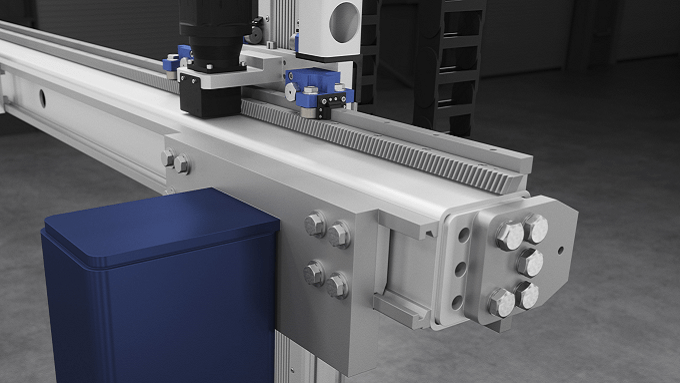

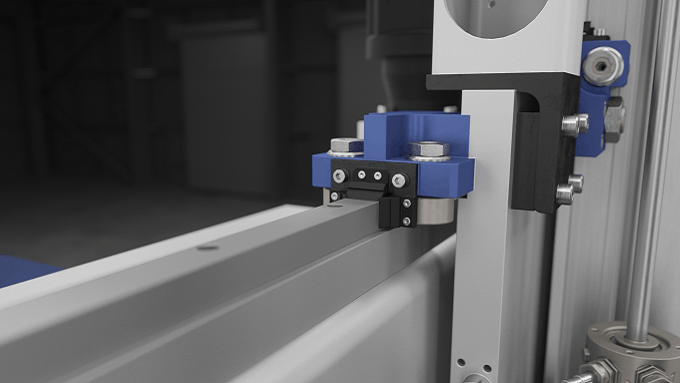

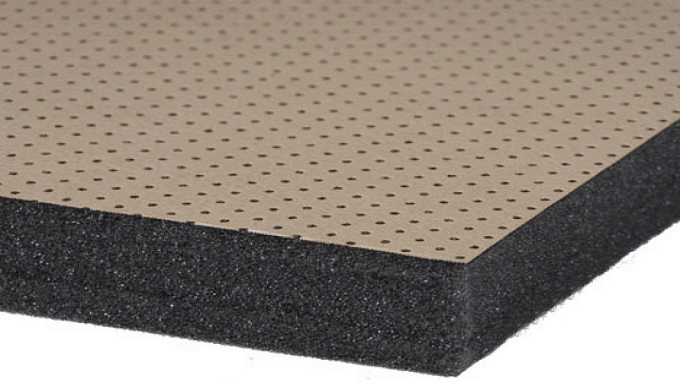

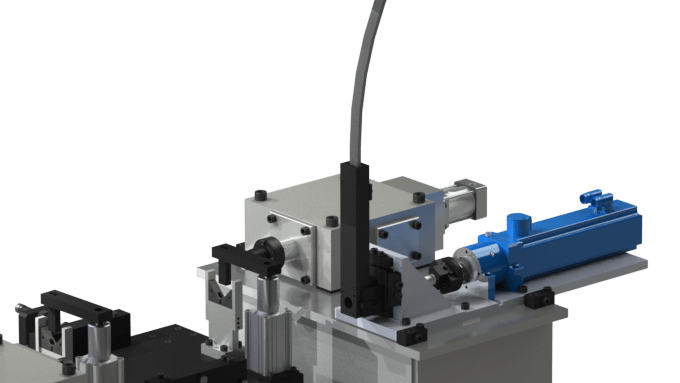

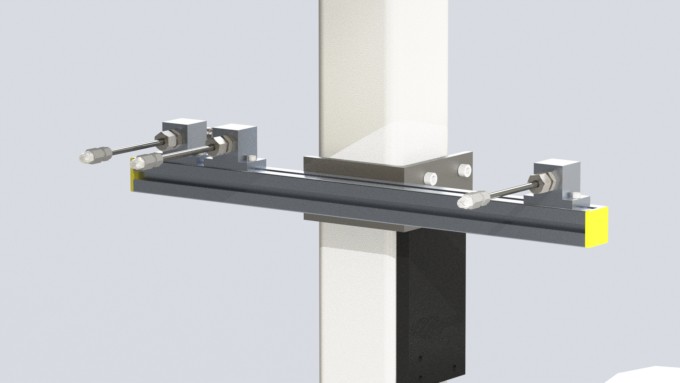

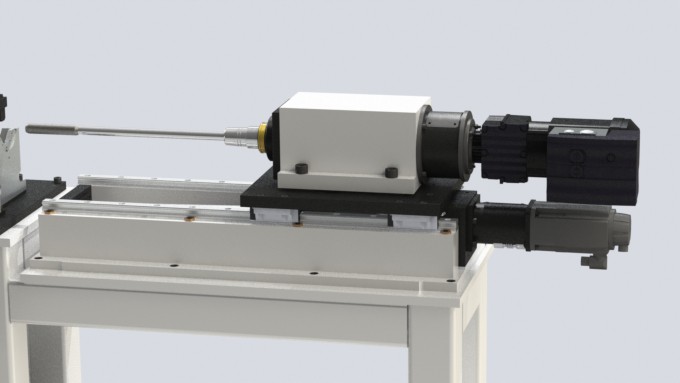

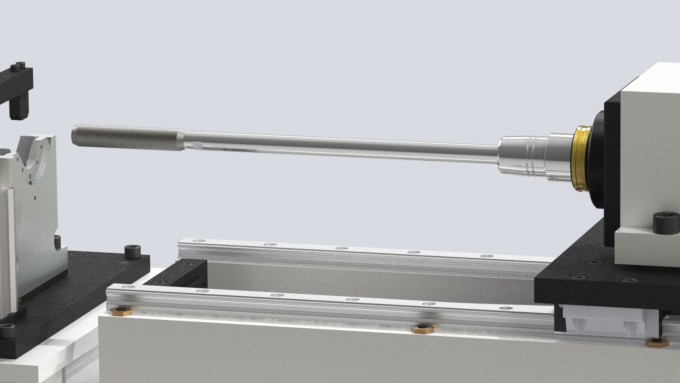

- High-precision standard machine parts.

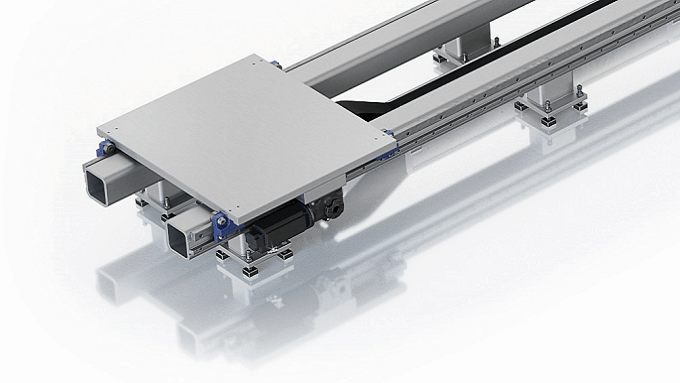

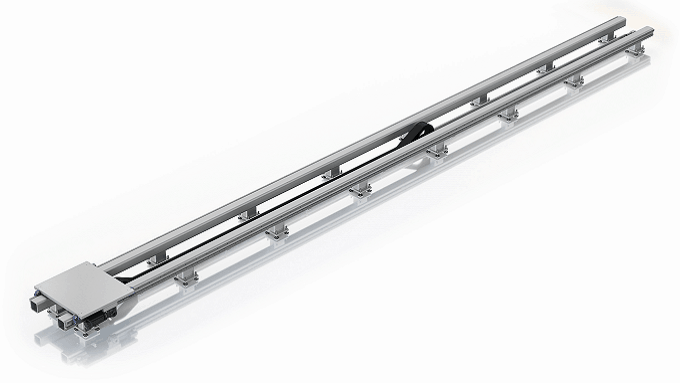

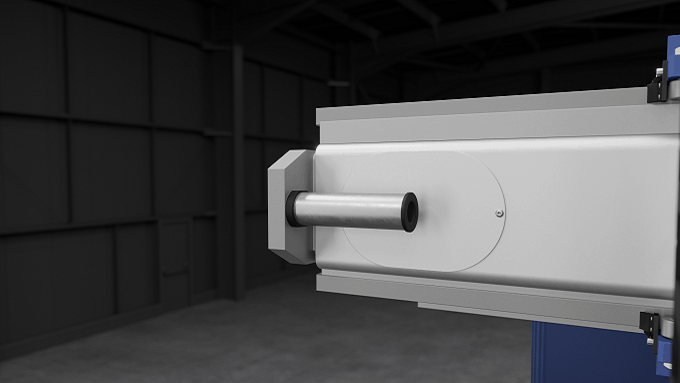

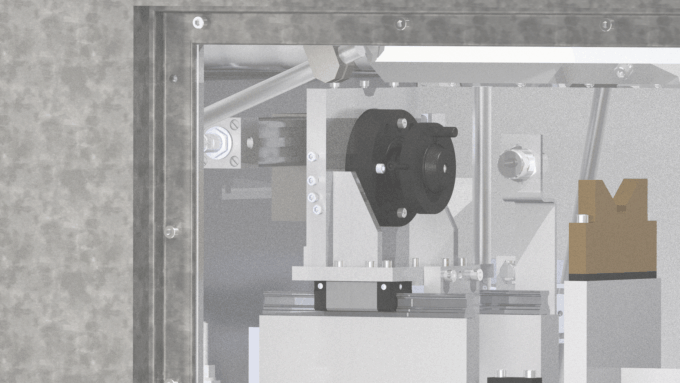

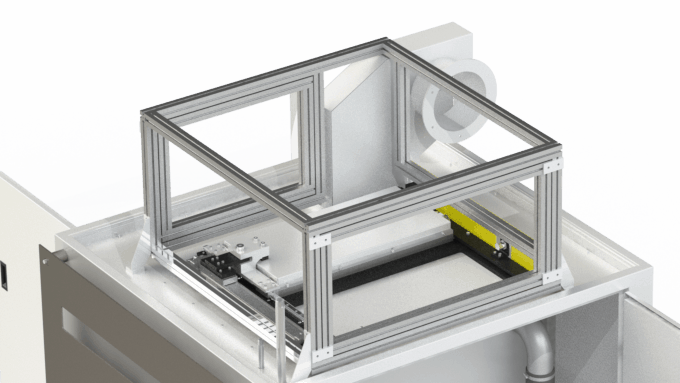

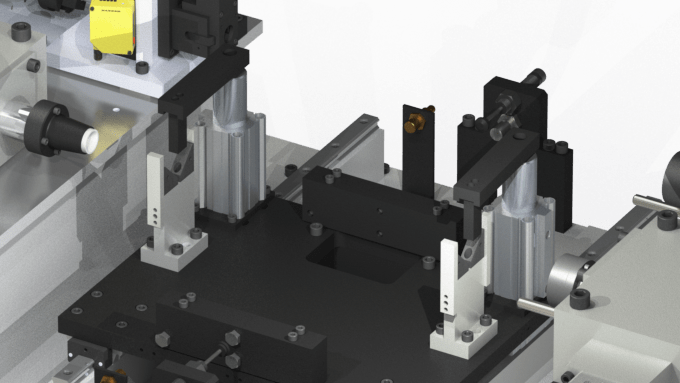

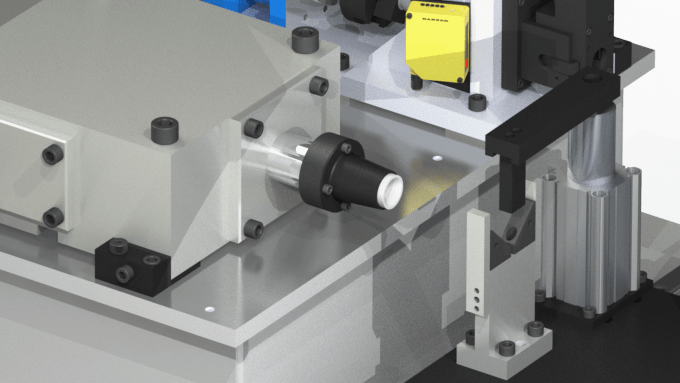

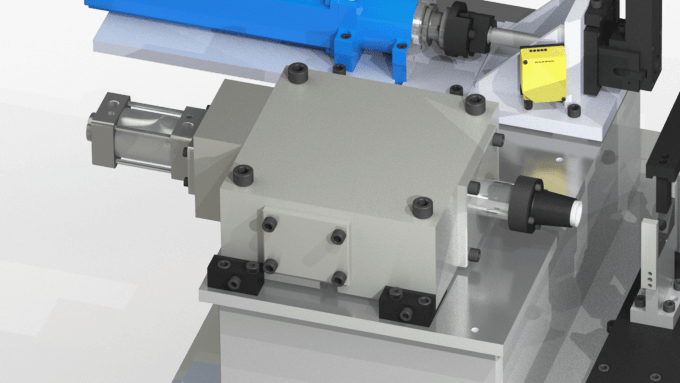

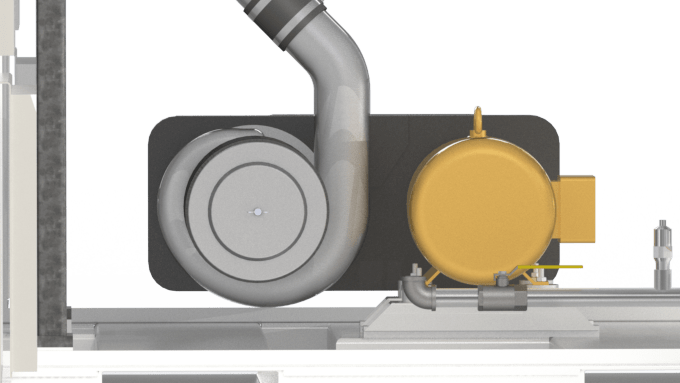

- Rotary tables to optimize customer production lines with high-accuracy positioning.

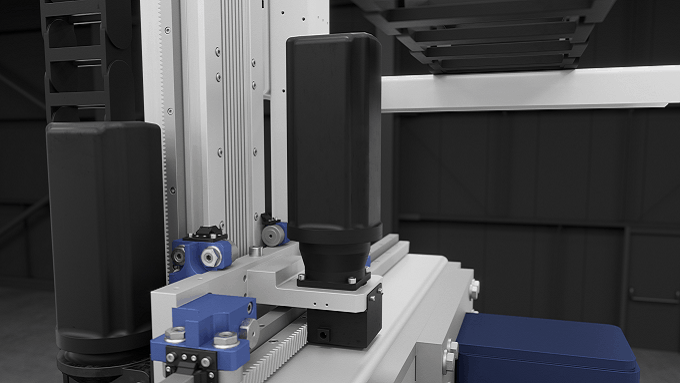

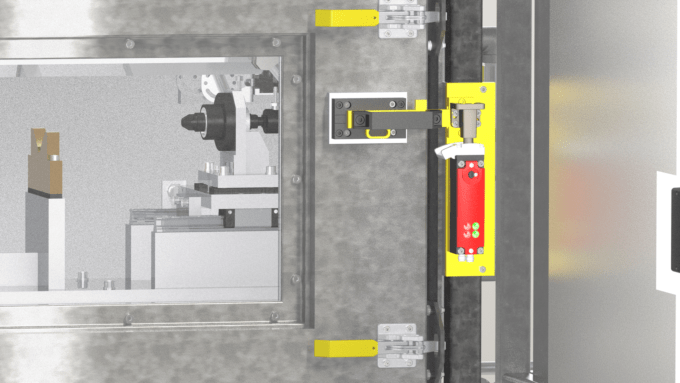

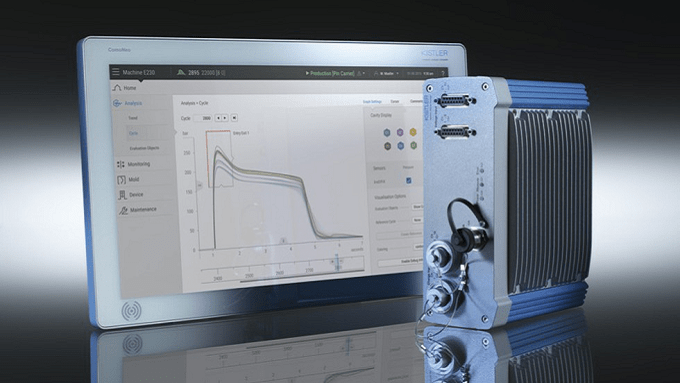

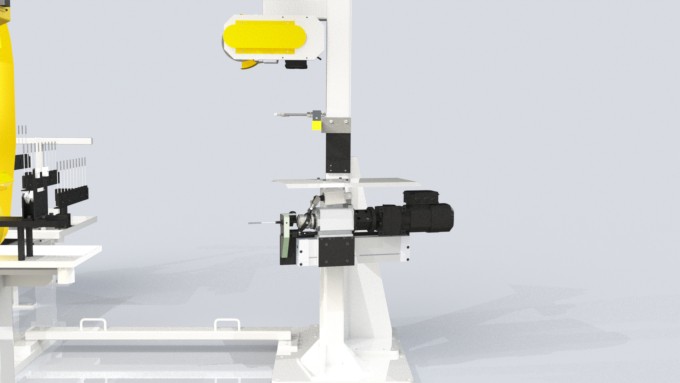

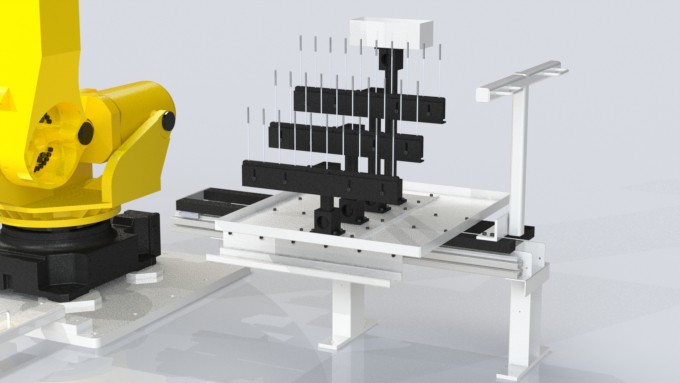

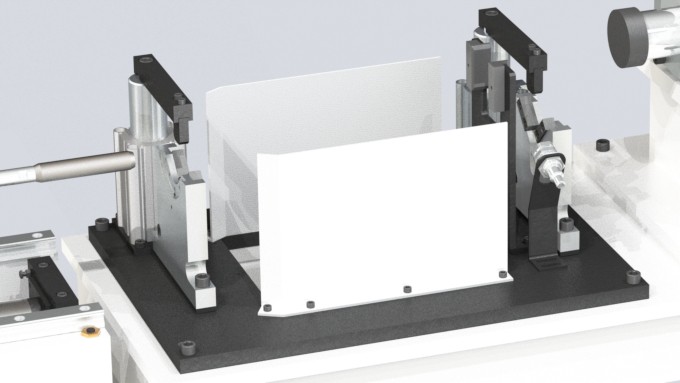

- Precision system engineering automating customer manufacturing processes.

- Training skilled workers of the future.

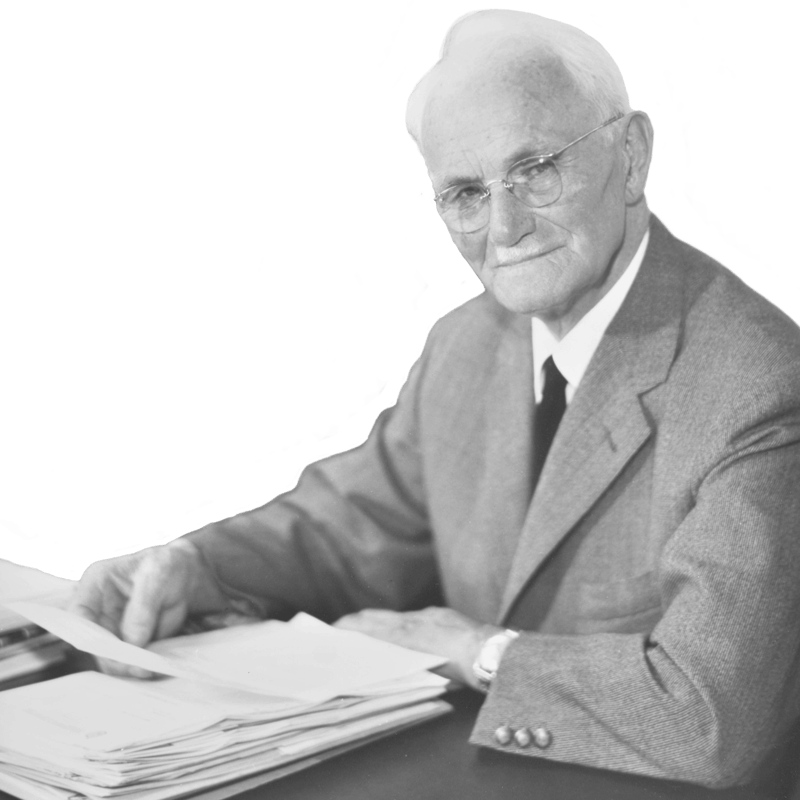

AUGUST LÄPPLE

MAN OF ACTION, FREE THINKER, PIONEER

Even as a young apprentice, August Läpple demonstrated intellectual curiosity, diligence and determination. He became a skilled toolmaker with considerable technical aptitude and the ability to think ahead. After working for various companies, including Bosch, the Esslinger Maschinenfabrik and the Neckarsulm Vehicle Works, he set up his own company in a time of economic and political troubles. Despite the difficult times, his company quickly flourished due to his boldness as an entrepreneur and keen interest in technical progress and innovation.

His family and friends knew him as a warm and generous man. He and his wife, Johanna, had three children. August Läpple passed away November 6, 1968 at the age of 83.

1919

FOUNDATION

It all began on 1 April 1919 with the courage of August Läpple founding a small mechanical workshop in Weinsberg, complete with a smithery. His first jobs were repairing bicycles and agricultural machinery, as well as manufacturing mower blades.

1920

MAJOR ORDERS FROM THE AUTOMOBILE INDUSTRY

In the 1920s, the automobile began its triumphant entrance into the world. This was good news for August Läpple. Early on, he manufactured tools for the automobile industry and acquired a core competence in the industry. He moved on to manufacturing car body parts in series using drawing technology he developed.

As early as 1928, he received his first large-scale auto parts orders, creating rapid growth for the young company. Customers included DKW, Hanomag and NSU.

1930

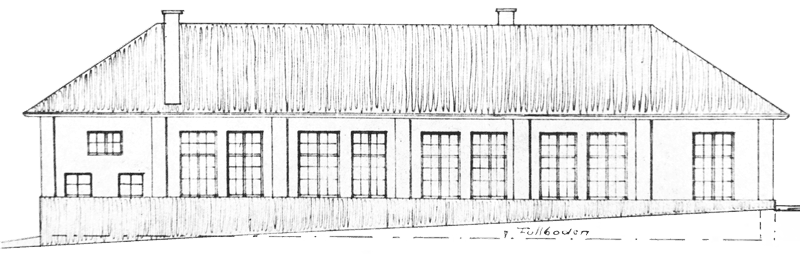

THE FIRST MOVE

Soon space became an issue on Heilbronner Strasse in Weinsberg. A large piece of land was purchased on Schwabstrasse 22 in Weinsberg, and a larger plant was built with room for expansion.

A workforce of 18 was now producing non-cutting shaping tools for sheet metal forming in the automobile industry.

1940

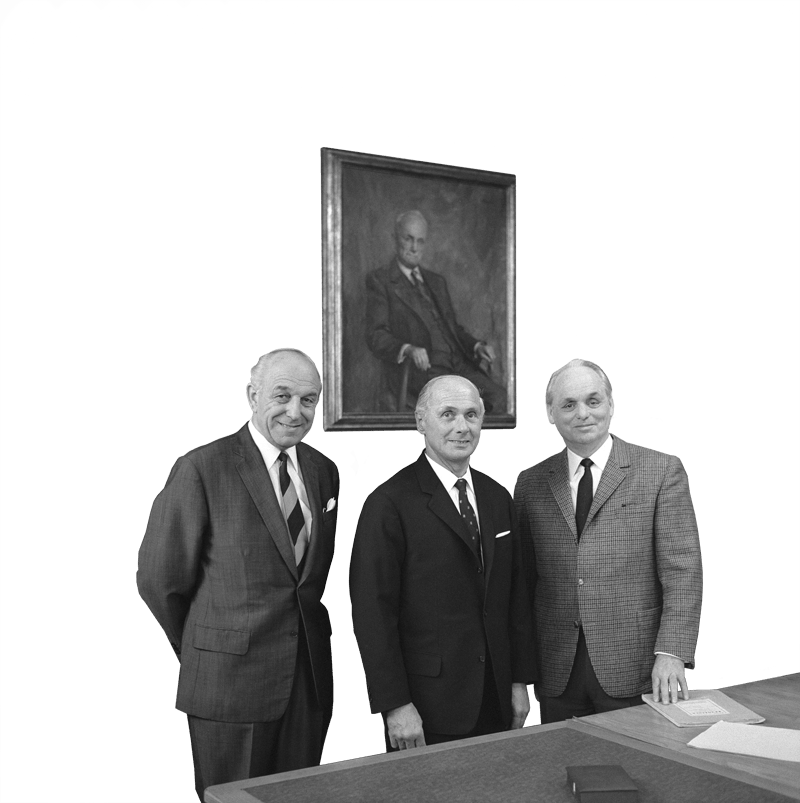

ENTER THE SECOND GENERATION

In 1940, August Läpple’s three children became partners in the company. His two sons took up positions in management, followed a short time later by son-in-law, Ernst Fleischmann.

They were a charismatic and dynamic trio. Erich Läpple’s focus and discipline in engineering led him to be responsible for technology. Helmut Läpple was a spirited and decisive man with the ability to inspire others. Ernst Fleischmann frequently assumed the role of mediator with his level-headed nature and flair for technology.

1945

LÄPPLE DEMONSTRATES ADAPTABILITY

Following the Second World War, there were years of difficult times with the destruction from the war, shortage of materials and restrictions on producing automobiles. August Läpple, and the second generation, launched many new products. They manufactured high demand items such as window fittings, keys, door handles, locks, building fittings, kitchen stoves, and bathtubs.

This flexibility enabled the company to survive bad times and retain its skilled workforce.

1950

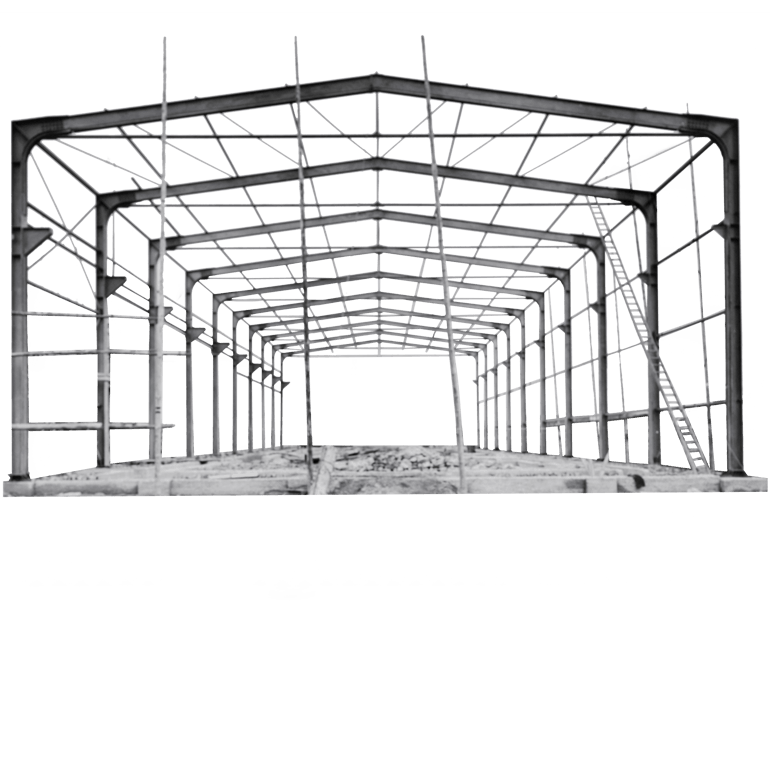

THE MOVE TO HEILBRONN

With the economic boom came an increase in orders and the company outgrew its plant in Weinsberg. Purchasing a 20-acre parcel in a new industrial estate, in Austrasse in Heilbronn, Läpple built and moved into three new plants in December 1950.

This Heilbronn site is still the headquarters of the LÄPPLE Group. It has been expanded and upgraded many times, but the plant walls built in 1957/58 are still in place today.

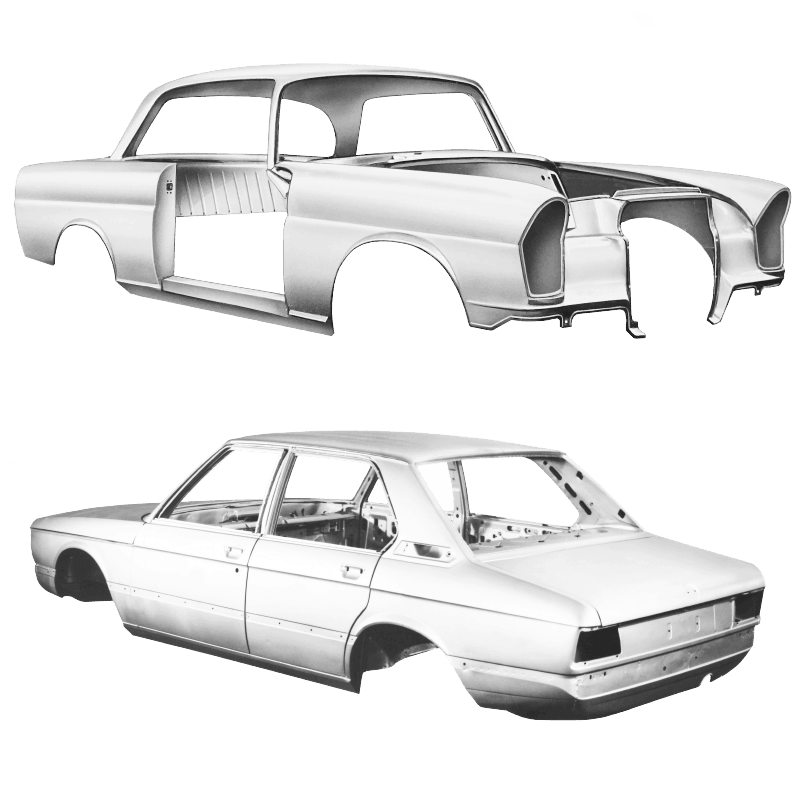

1950-1960

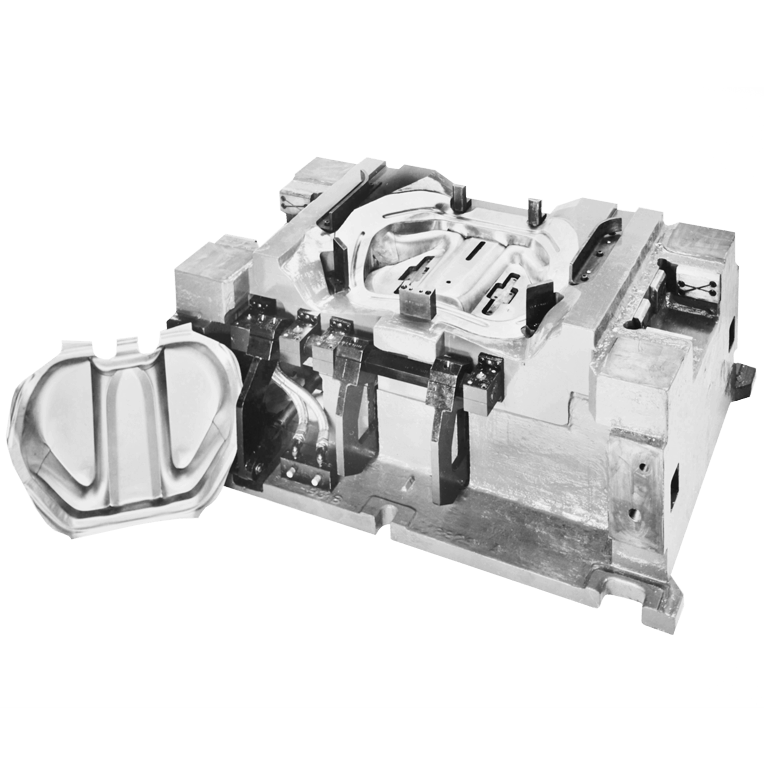

TWO PILLARS – TOOL CONSTRUCTION & METAL STAMPING PLANT

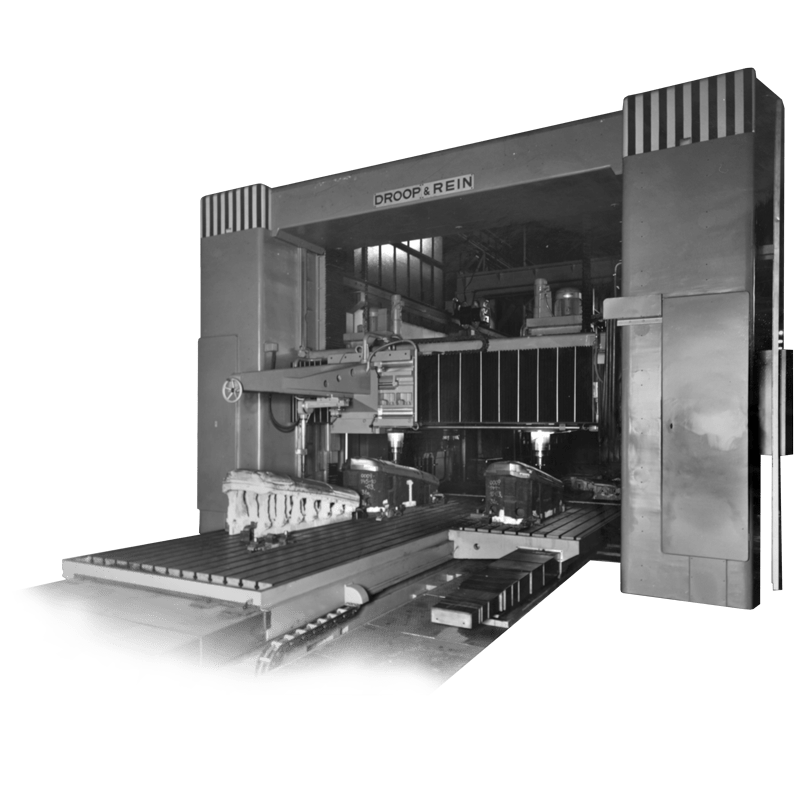

LÄPPLE’s strategy in the 1950s and 60’S focused in two areas:

- Designing and producing tools for metal forming and stamping.

- A metal stamping plant, with the latest equipment, able to produce large stamped parts, in high quantities.

Such a combination worked well. Toolmaking requires long lead times for planning, construction and testing, while the production of stamped parts is a steadier business.

LÄPPLE now had more than 1,000 employees, supplying customers worldwide.

1965

FROM SUPPLIER TO SYSTEM PARTNER

To expedite production engineering, automobile manufacturers began to involve LÄPPLE in the development of new vehicle models. LÄPPLE worked together with its customers to design and manufacture the necessary tools – becoming a system partner rather than just a supplier.

Technology kept moving forward as well – using the latest digital technology, the first three-dimensional measuring machine for large workpieces went into operation in 1965.

1974

ACQUISITION OF FIBRO GMBH

On December 1, 1974, LÄPPLE purchased FIBRO GmbH, a manufacturer of standard parts for tool construction and rotary tables. Based in Weinsberg and Hassmersheim, Fibro is still a part of LÄPPLE Group today and has earned a name for itself as a successful player in the market.

Customers appreciate the high precision and availability of its wide range of standard parts and comprehensive rotary table product line. Their global presence includes 7 international subsidiaries and more than 70 representatives worldwide.

1986

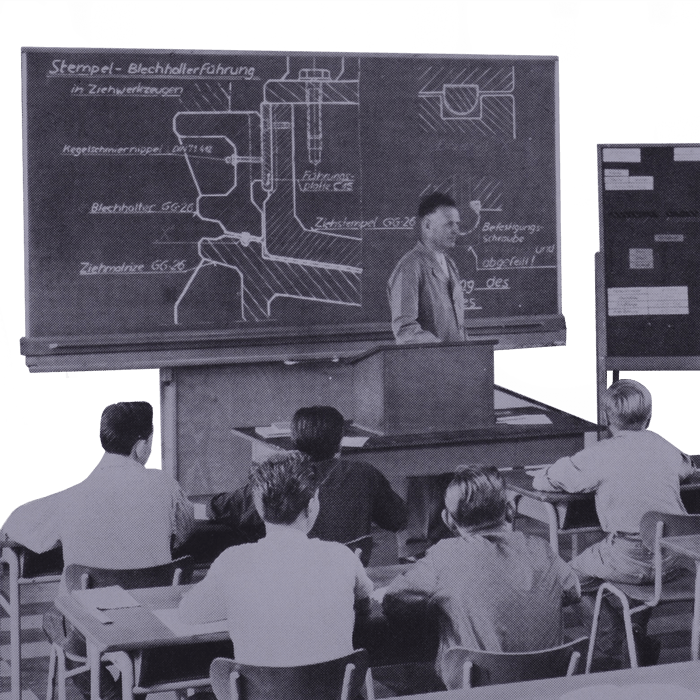

FROM AN APPRENTICE SCHOOL TO A TRAINING CENTRE

What began with one single apprentice in August Läpple’s metalworking workshop in 1919 has now become an independent company with more than 200 apprentices and students trained every year.

A separate department, the “Apprentice School”, was established as early as 1930. In 1965, it moved to new and larger premises on the Heilbronn site. In 1986, the LÄPPLE Training Company was founded as part of August Läpple GmbH.

With its unique training philosophy, LÄPPLE Group has secured its skilled workers of tomorrow.

1990

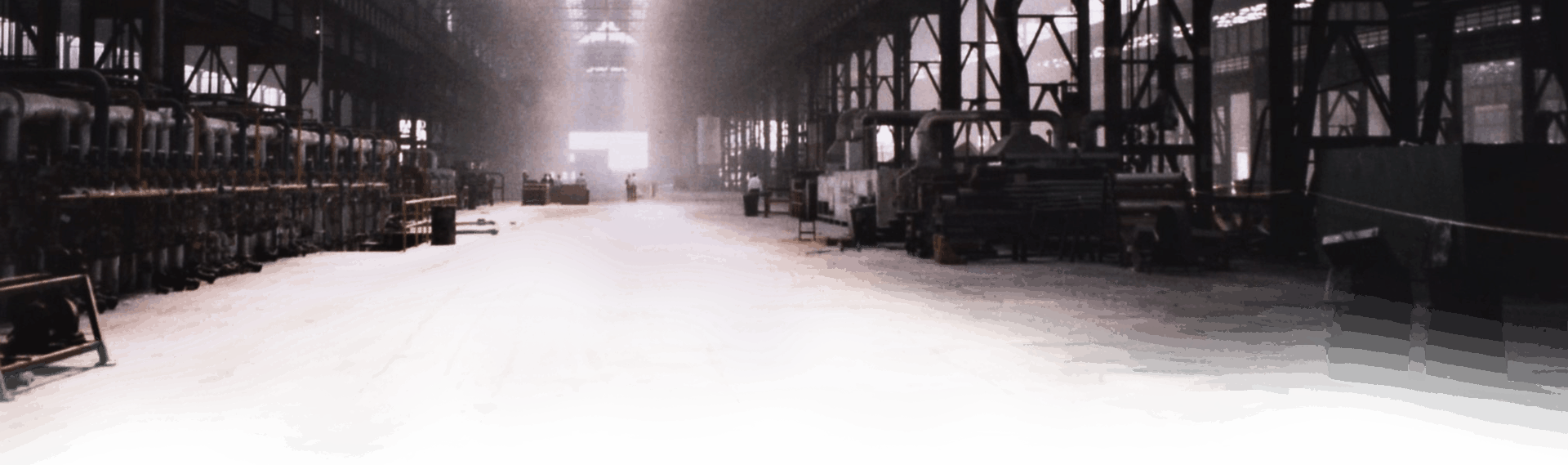

NEW SITE IN TEUBLITZ, BAVARIA

Once again reaching capacity limits, and with the automobile industry booming, a former cold rolling plant in Teublitz offered proximity to long-standing customer BMW. Helmut Laepple purchased the 100-acre site with buildings and railway sidings, in September of 1990.

Conversion and renovation work finished in May 1991 with the newly founded “LÄPPLE Sheet Metal Processing GmbH & Co. KG Bayern” beginning production of parts for the AUDI 80 convertible.

Today, this plant, and the plant in Heilbronn, are part of LÄPPLE AUTOMOTIVE GmbH.

2002

CHANGE OF NAME – LÄPPLE AG

In 2002, the LÄPPLE partners implemented a plan for sustainable succession, transferring all activities to the legal form of a stock corporation, retaining 100 percent family-ownership still today.

Following the retirement of the second generation, on April 1, 2004, an externally appointed chairman took over the management. He is assisted by a chief financial officer. A principle which has proved its worth through present day.

2008

EXPANSION: NEW FIBRO PLANT IN INDIA

FIBRO set up a new plant in Pune, India in 2008. Beginning in rented premises, its quick success required a move in 2019 to the first buildings owned by the company. Production was originally standard parts but later expanded to also manufacture rotary tables. Land adjacent to the site was purchased to expand production, and the official opening ceremony for Plant 2 took place in February 2019.

2010

AN UNBEATABLE COMBINATION – FIBRO LÄPPLE TECHNOLOGY

Prior to 2010 our automation technology was in two divisions, LÄPPLE Automation at the company’s main location in Heilbronn and part of FIBRO-GSA Automation GmbH in Hassmersheim. Their product range was similar, but each had a different market focus.

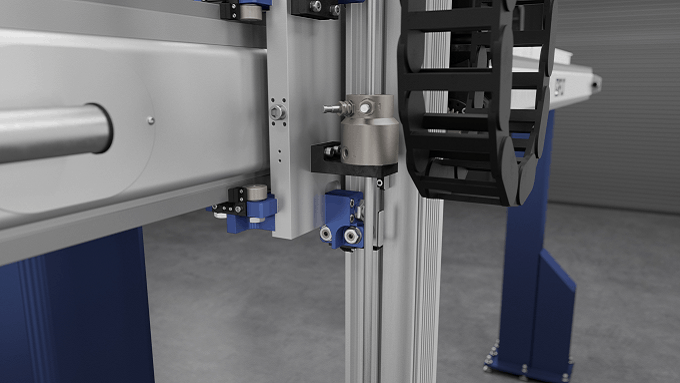

Their different strengths were brought together in 2010 in FIBRO LÄPPLE TECHNOLOGY GmbH (FLT). The product portfolio was consolidated, and FLT soon established itself internationally as a supplier of highly effective automation solutions.

2016

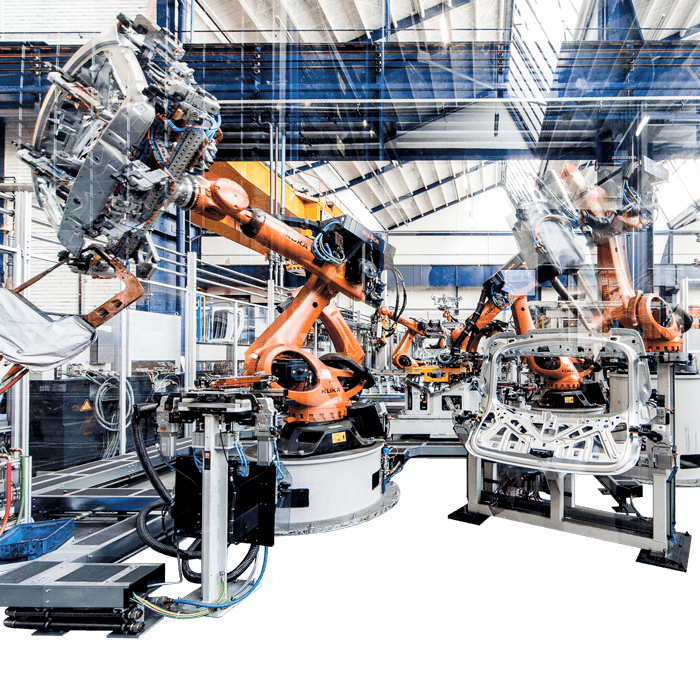

FROM STAMPED PARTS MANUFACTURER TO MODULE SUPPLIER

Rather than stamped sheet metal parts, customers were now looking for structural parts and assemblies of structural parts forming complex body modules. The company responded to this trend in 2016, investing in a new transfer press with ServoDirect technology for its Heilbronn site.

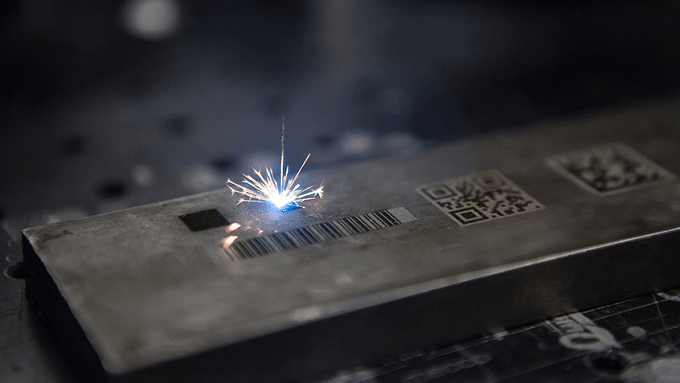

Investment in joining technologies also helped to serve expanding customer requirements. Our shell construction division grew, with new processes in laser welding, aluminum spot welding, friction element welding and flow drill screws.

2019

FOUNDATION OF LÄPPLE TAICANG

2019 sees LÄPPLE expanding to the world’s largest automobile market – China. Recognizing potential for all companies in the group, LÄPPLE Taicang, was founded to bundle the activities of FIBRO, FLT and LÄPPLE AUTOMOTIVE.

ONWARD TO

A SUCCESSFUL FUTURE

Over the last 100 years, LÄPPLE has reinvented itself again and again: It has adjusted to changing market conditions, introducing innovative products and services. LÄPPLE Group continues to develop itself as a system partner to our customers. Since 1919, our task, and success, is increasing customers’ productivity.

Like the motto “If you don’t go forwards, you’re moving backwards,” from August Läpple, LÄPPLE Group strives consistently to offer its customers optimized solutions.

Our focus remains on the major trends in LÄPPLE’s markets: digitalization, networking, alternative drive systems, light construction and internationalization. LÄPPLE is taking up these challenges and preparing for the next 100 years through consistent knowledge development, integration of smart technologies, and sensor systems, and, further development of its own footprint.

FACTS AND FIGURES OF THE

LÄPPLE GROUP

- Sales in 2018: 521 million euros

- Employees: approx. 2700

- Sites in Germany

- Hassmersheim, Heilbronn (headquarters), Teublitz, Weinsberg

- Sites around the world

- FIBRO: Shanghai, China; Schiltigheim, headquarters; Bielsko-Biała, Polska; Pune, India; Singapore; Incheon, South Korea; Rockford, USA

- FLT: Shanghai, China; Windsor, Canada; Sterling Heights, USA