NEW SOLUTIONS

INNOVATION BY FLT

Quicker, better, lighter, and more connected – continuous development, continuous improvement – this is the mission of FLT to overcome the challenges in production.

Collaboration with customers and vendors allows us to stay at the forefront of technological developments.

DIVERSE INNOVATIONS

OUR NEW PRODUCTS

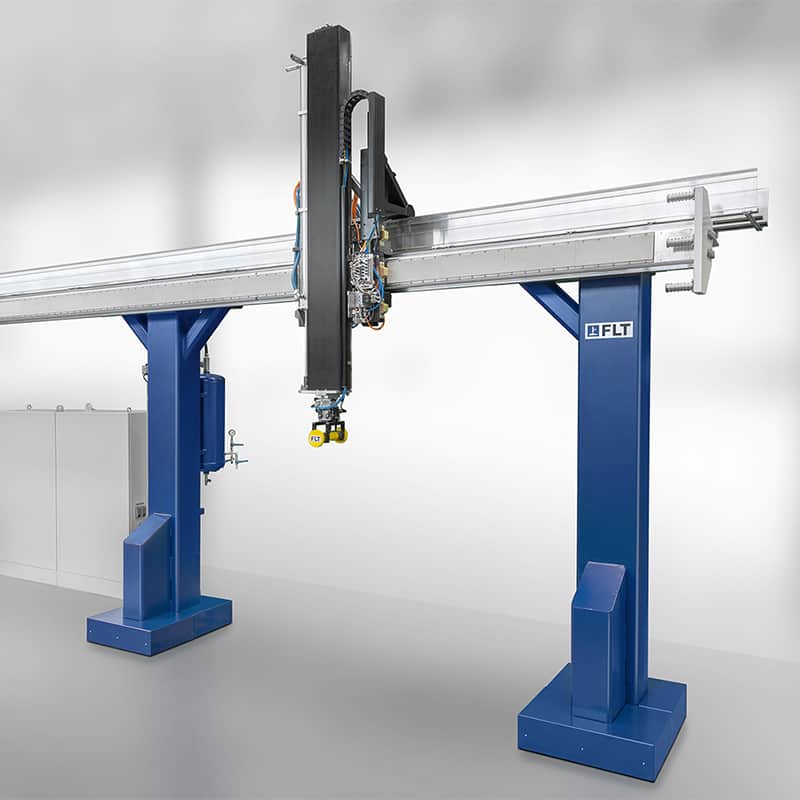

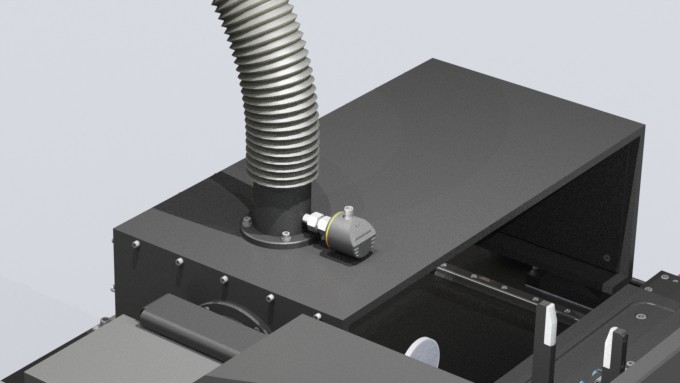

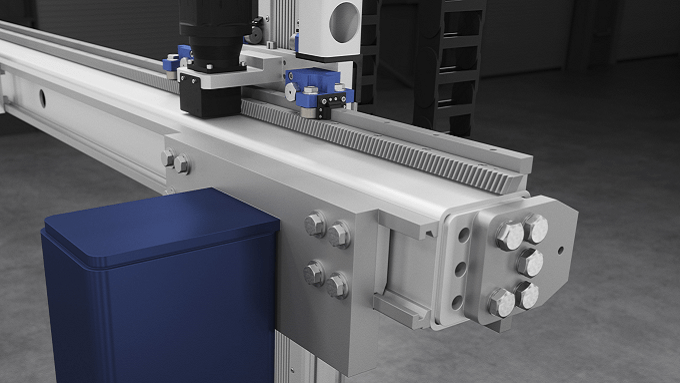

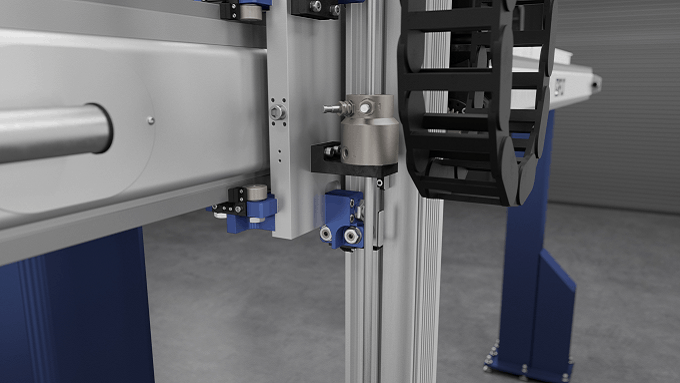

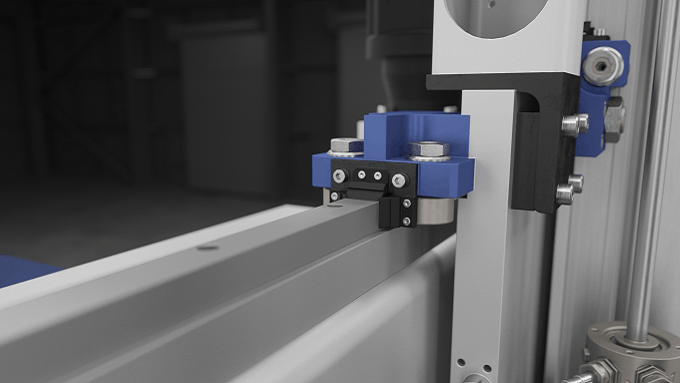

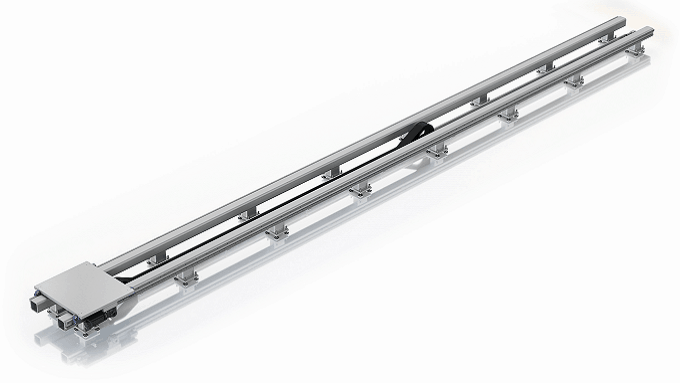

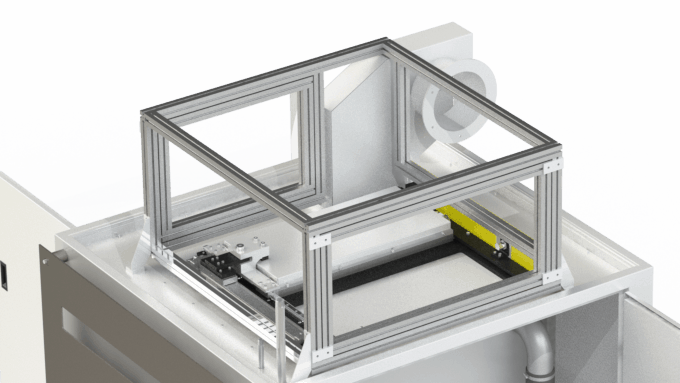

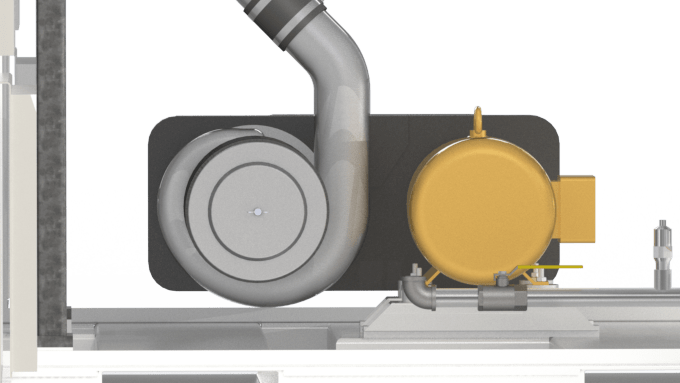

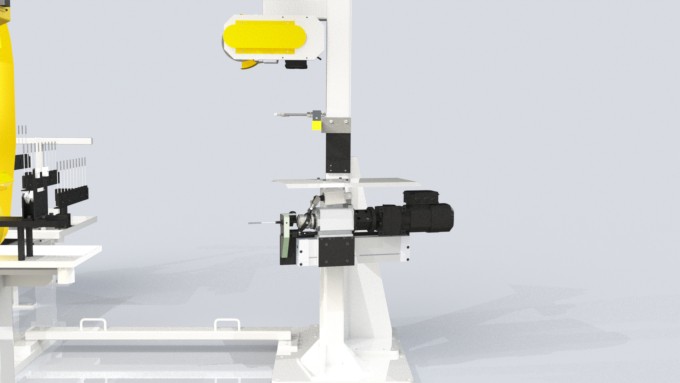

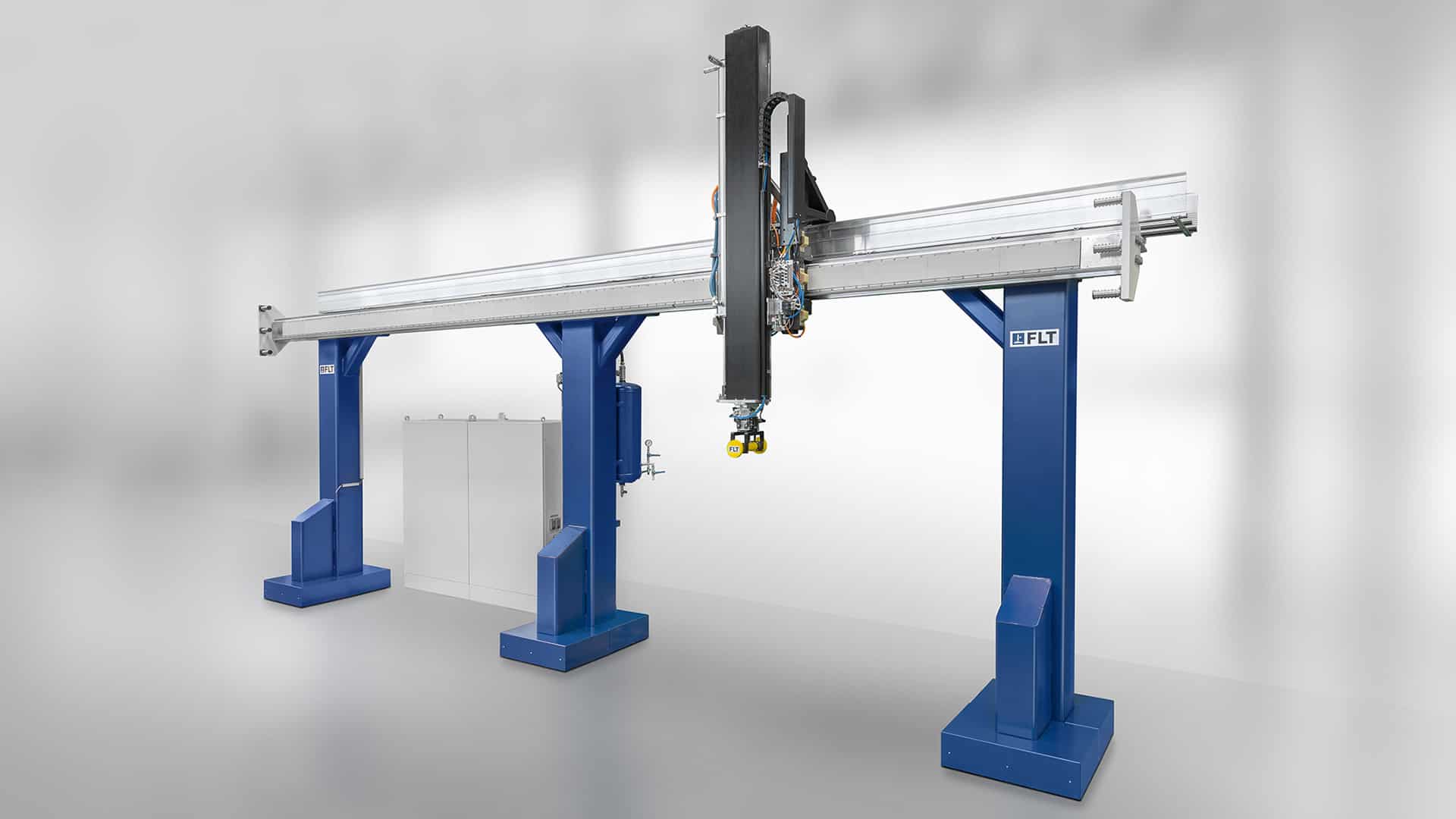

LINEAR DRIVES

FLT linear drive gantries offer many advantages:

- Quicker acceleration and shorter cycle times.

- Movement is more dynamic without sacrificing precision.

- Increased output.

- Easy to install, require less space, energy efficient and a long operating life.

- Require much less maintenance than conventional systems as they use fewer mechanical machine elements.

Want to know more information about our linear drive gantry? Get in touch with our sales team.

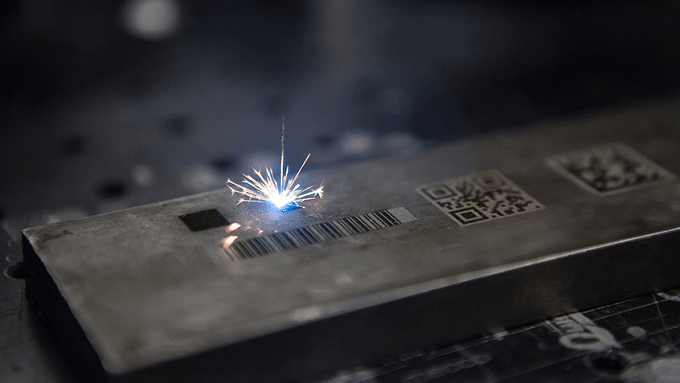

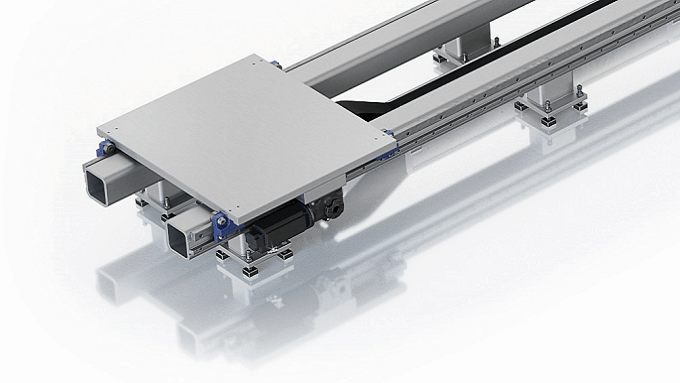

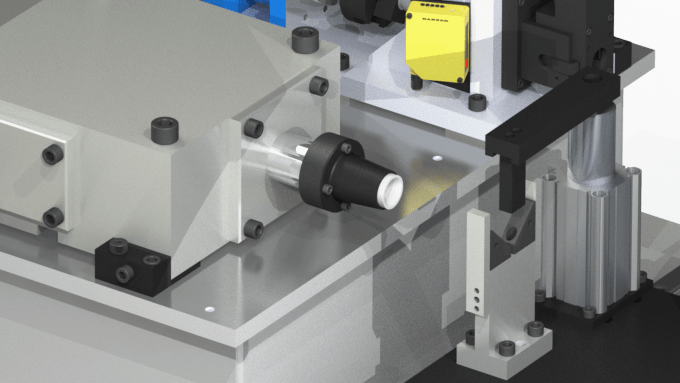

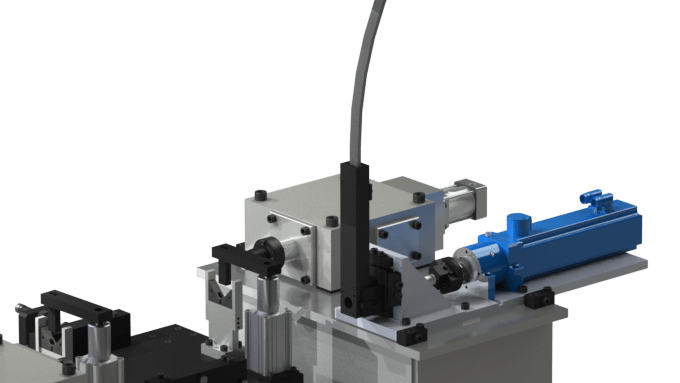

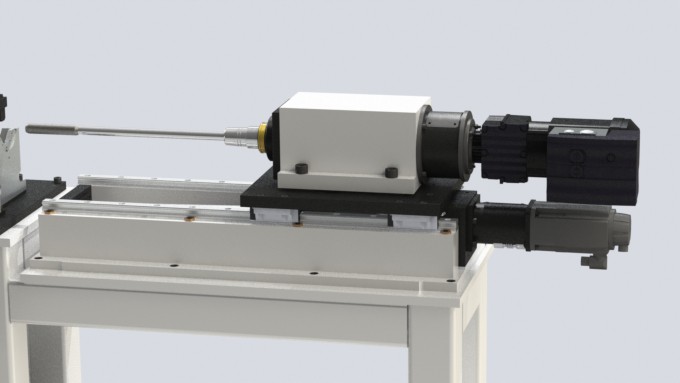

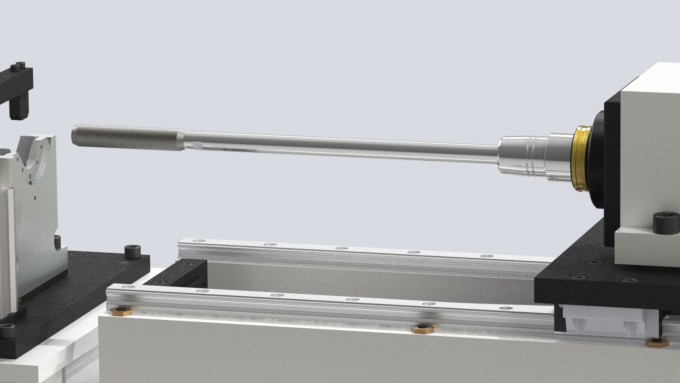

LIGHTWEIGHT CONSTRUCTION

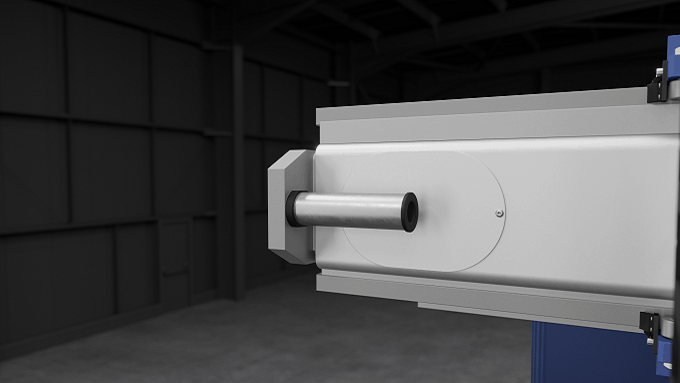

Lightweight construction results in significant added value in systems engineering, particularly in high-performance and dynamic applications. For example, replacing a heavier material with CFRP creates new possibilities in high acceleration and high precision applications.

Using carbon in the carriage and the vertical axis reduces gantry tare weight and optimizes motion sequences. Also, carbon’s vibration-dampening properties eliminate the adverse effects of operating at high speeds.

FLT’s air-cooled linear motor achieves acceleration of several G’s on the horizontal and vertical axes. In addition, the integrated measurement system gives the carriage positioning precision that is not available from our competition.

It would be our pleasure to demonstrate the possibilities of using lightweight construction technologies in your specific application. Get in touch with our sales team if you are interested.

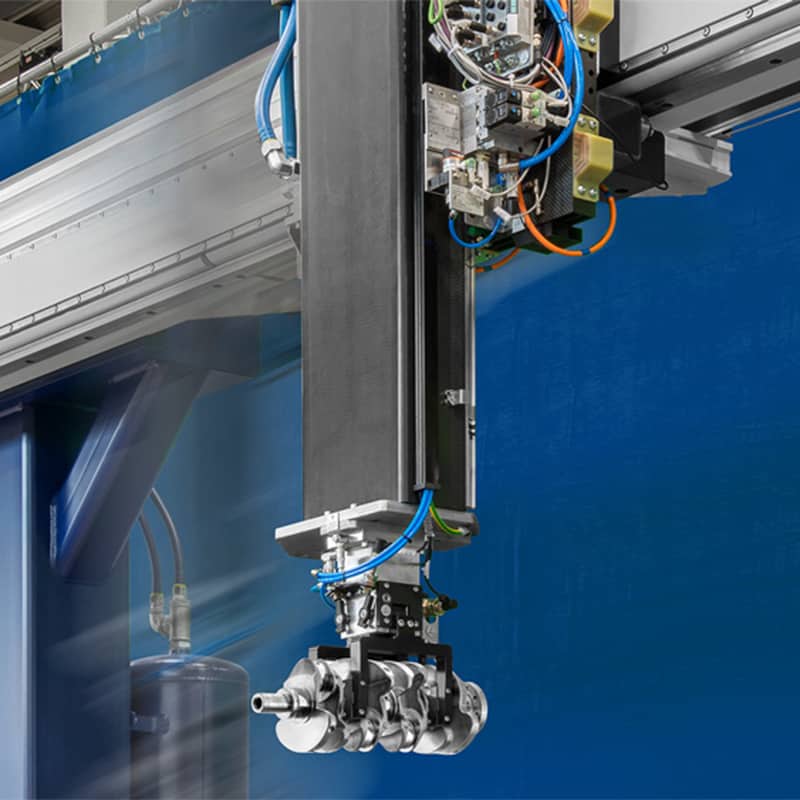

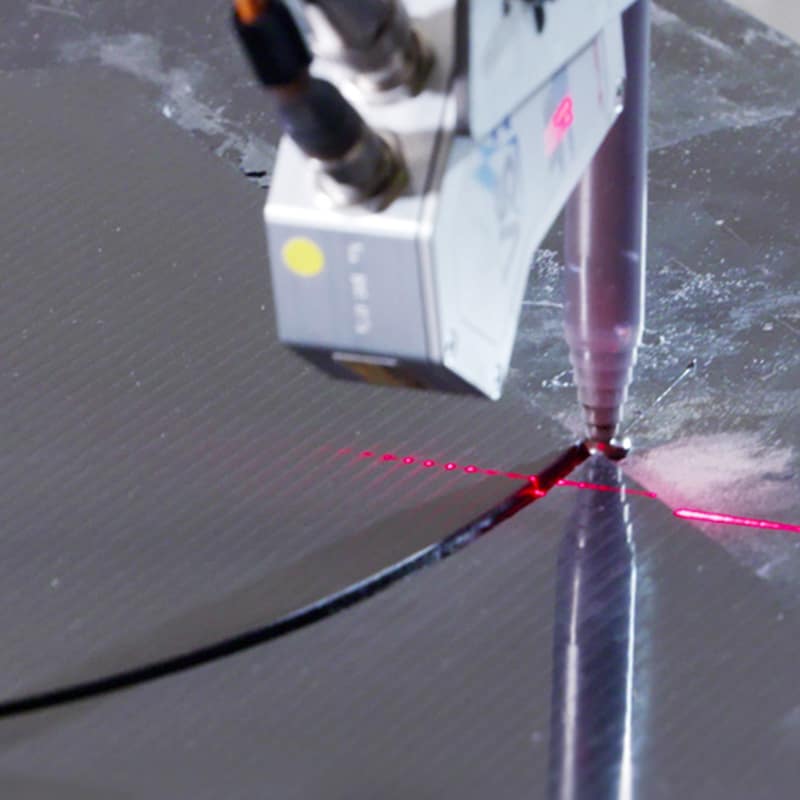

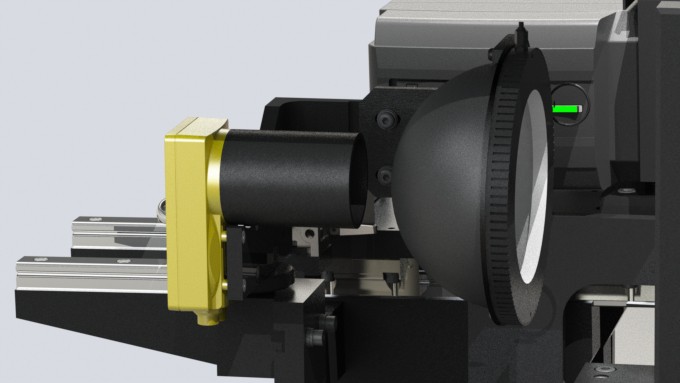

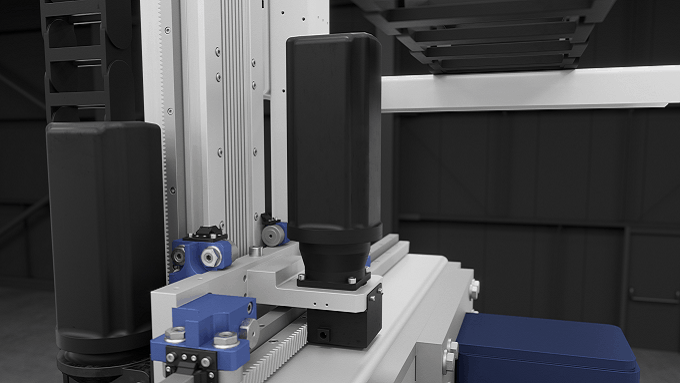

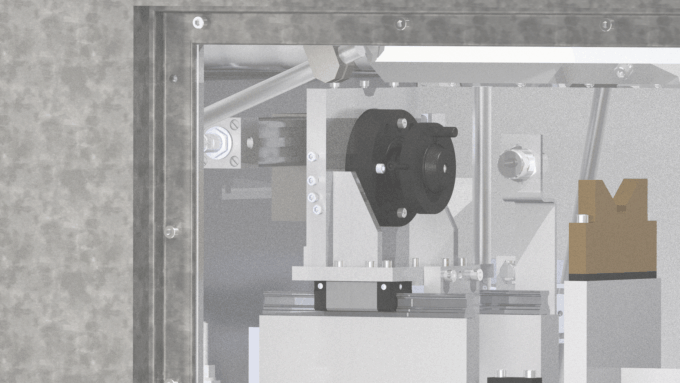

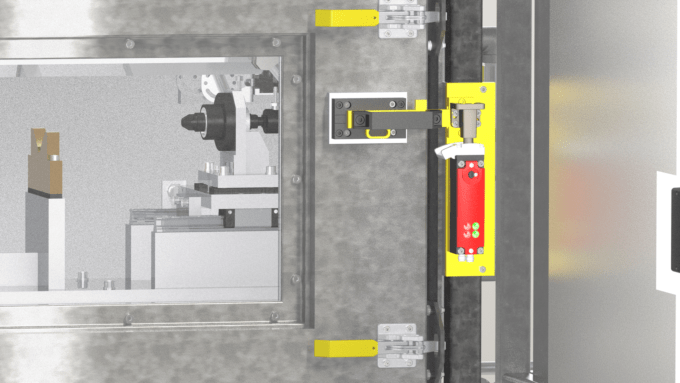

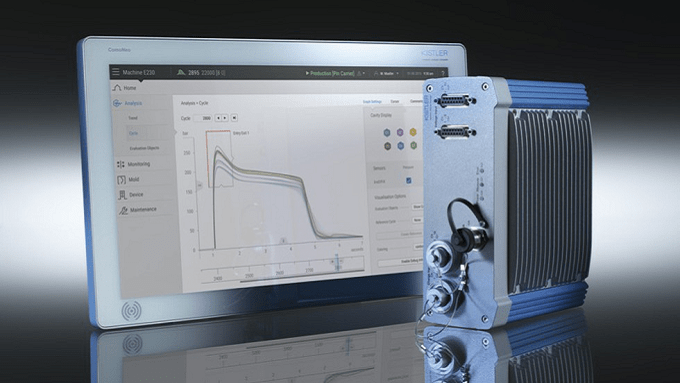

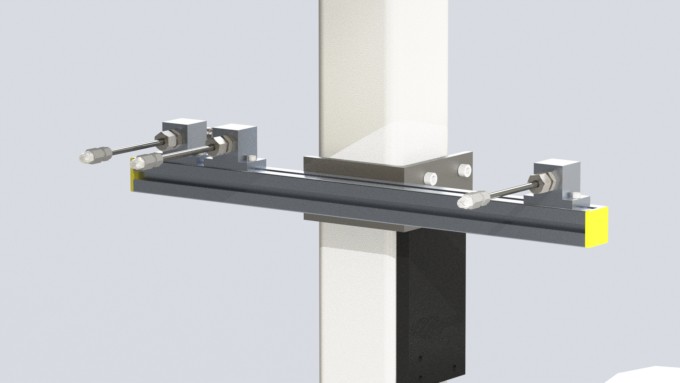

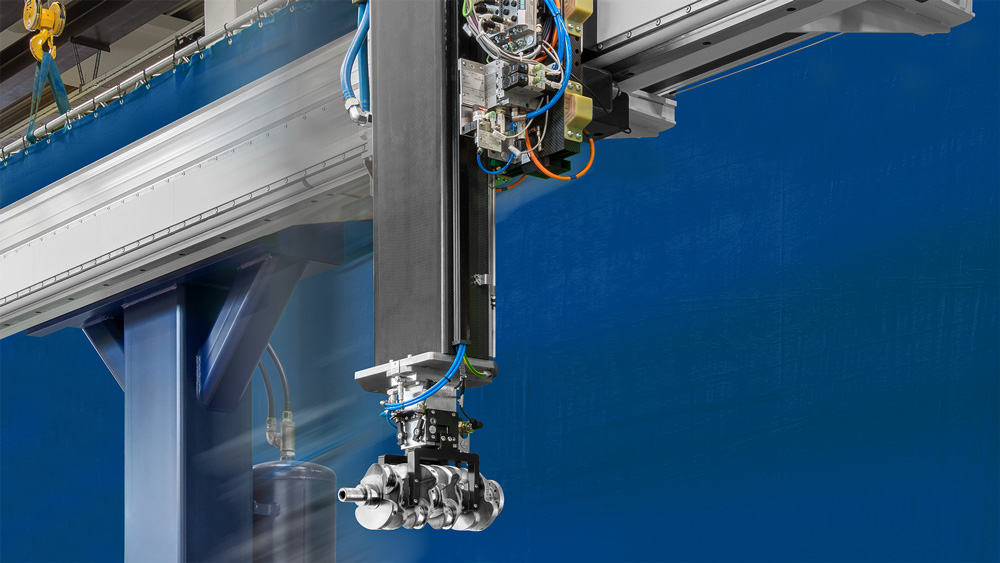

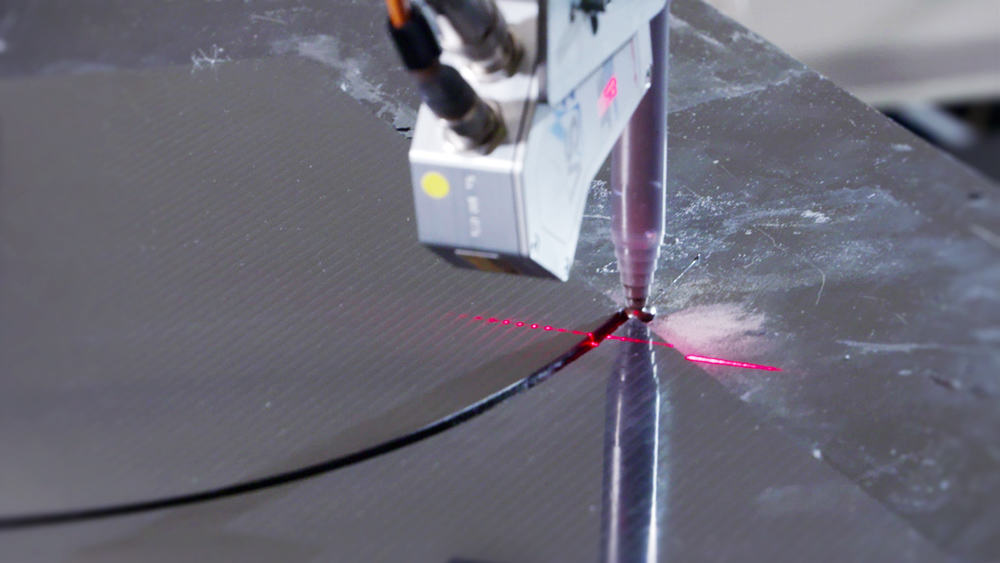

AUTOMATED EDGE SEALING

FLT’s automated edge-sealing application is an industry first that makes it possible to seal edges of large CFRP parts typically used in aviation and aerospace. An optical sensor detects and measures the gap. Sealant is calculated and precisely dispensed all in the same run.

Continuous measurement adjusts the quantity of adhesive to the variable gap and verifies application quality at the same time. Cycle time is reduced, and material waste eliminated. Health risks associated with the sealant can now be eliminated as employees no longer have to be in proximity.

This system works with robots or gantries.

2016

Our gantry robot for edge sealing won the AVK (German Federation of Reinforced Plastics) Innovation Award 2016 – one of the most prestigious prizes in the composites industry. This award was received by FLT and our partners DOPAG and EngRoTec.

2017

In 2017, our system won the MM Award innovation prize, which is awarded to the most innovative exhibits at the Automatica trade fair by the MM MaschinenMarkt trade journal. FLT came out on top in the “Assembly” category with the “gantry robot with edge-sealing application” and won the eminent award.

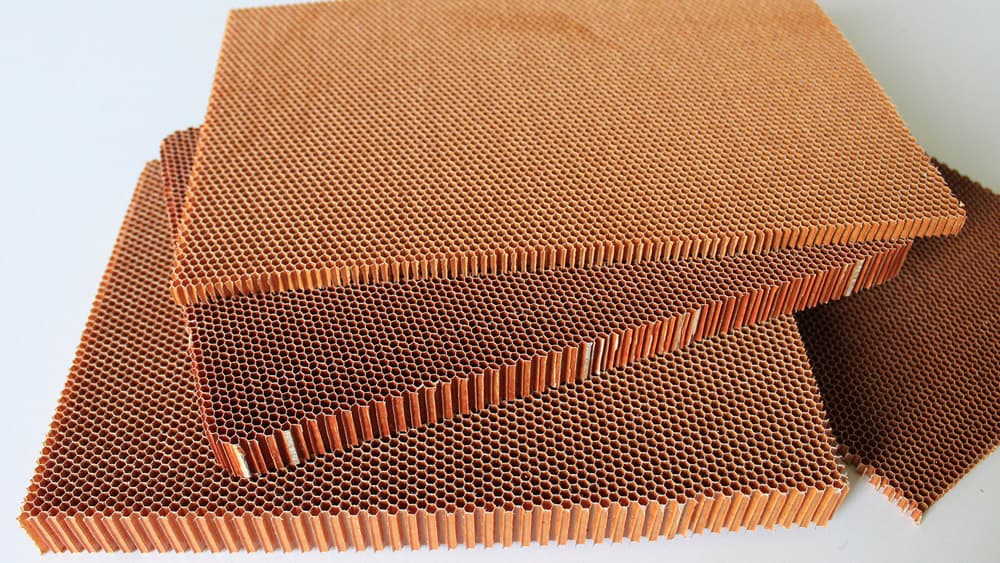

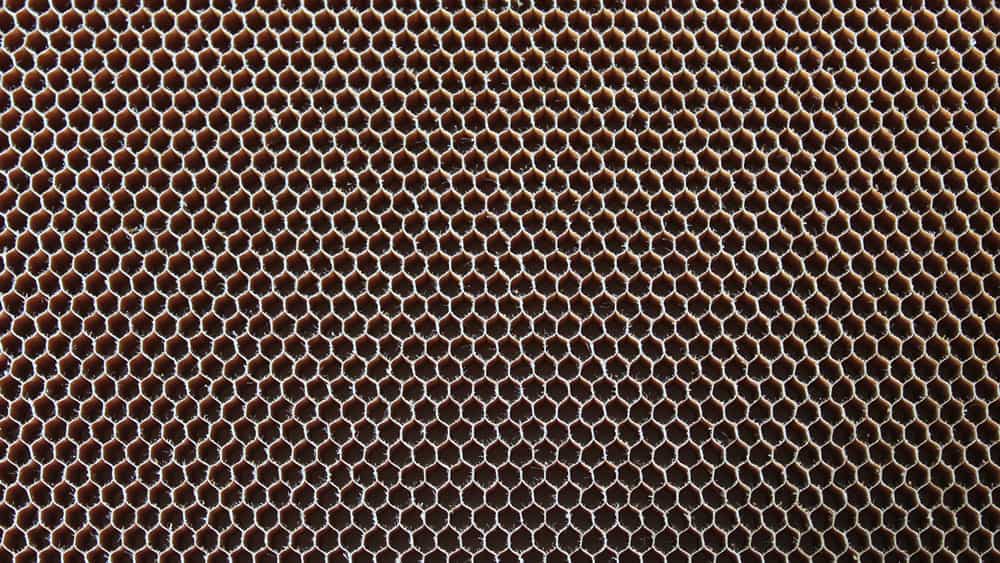

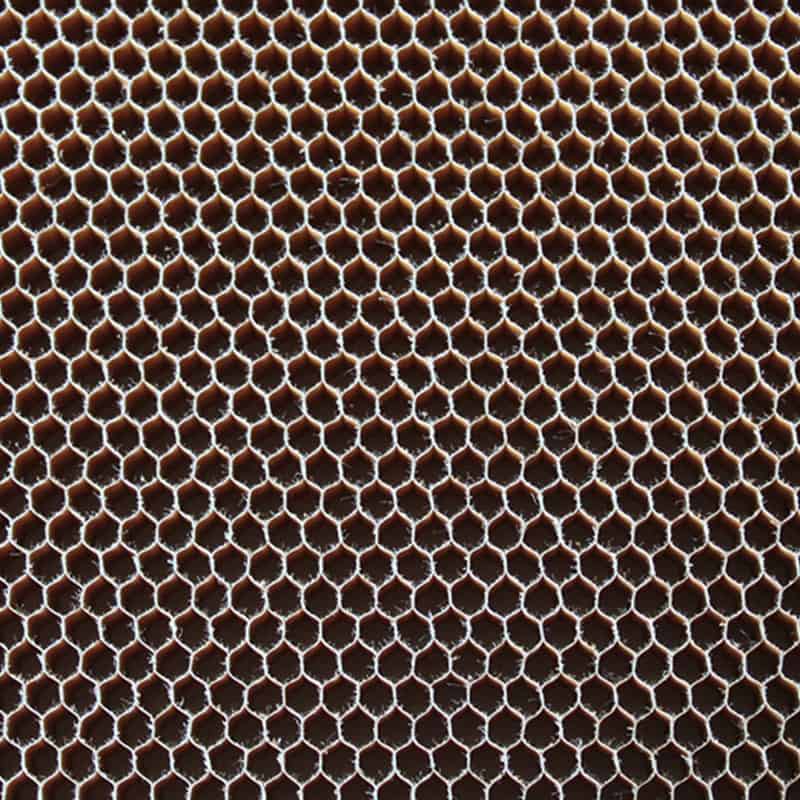

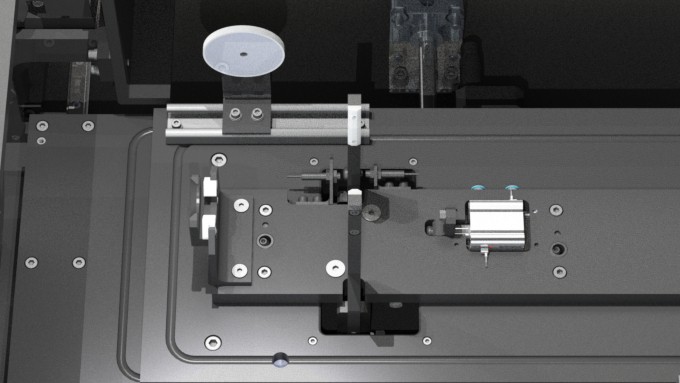

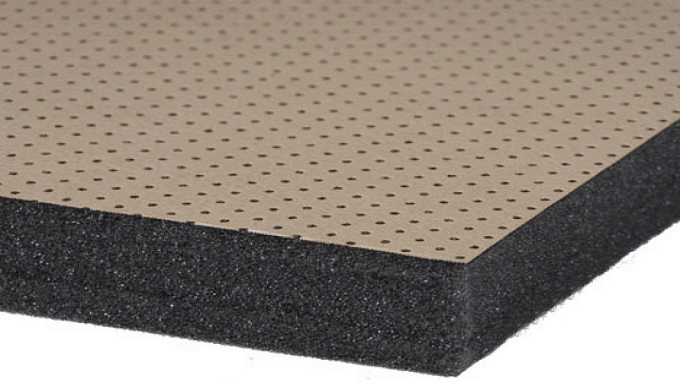

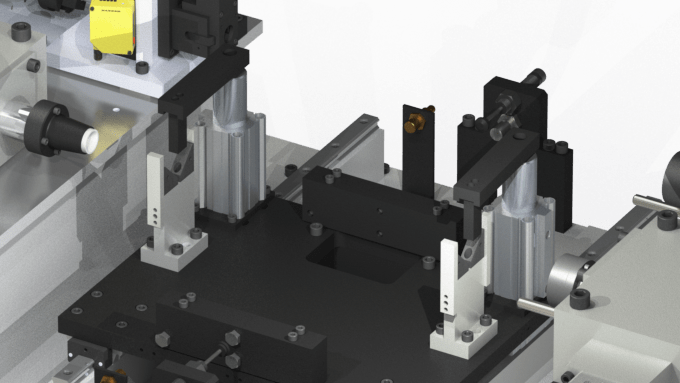

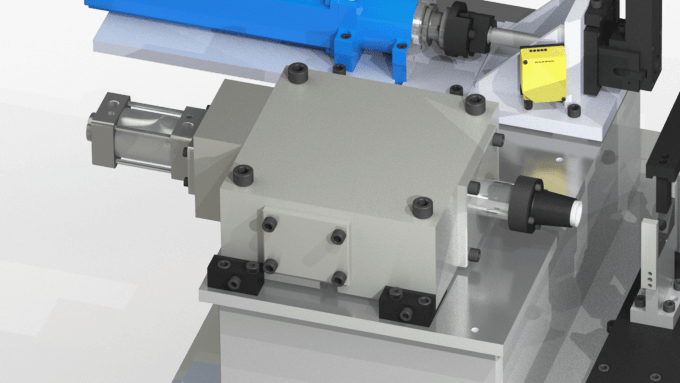

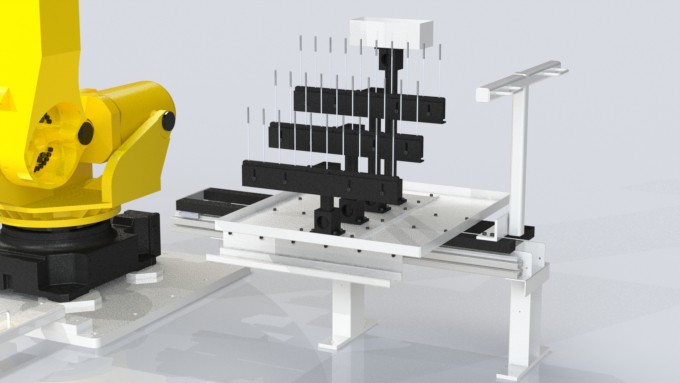

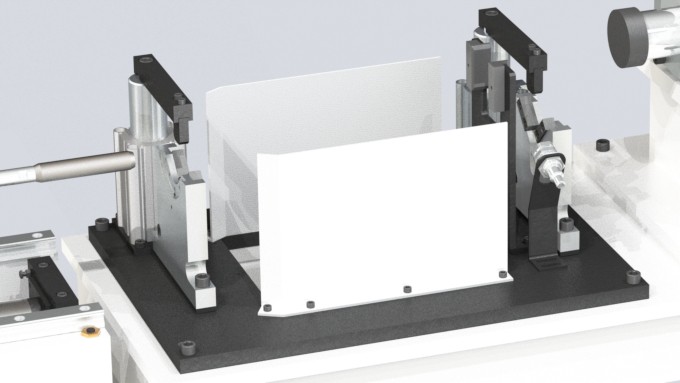

HONEYCOMB POTTING

Materials with a honeycomb structure made of aramid fibers are popular in aviation and aerospace applications because of their strength and light weight. Sealant is used to fill the hollow structures around the joining points, creating a hard surface for connection.

This had been a manual process that was difficult to quality check, but FLT has created an automated solution. The dispensing head moves over the honeycomb surface, calculating the correct amount of sealant material required, and validated by the system. Results are increased precision and elimination of rework.

This system works with gantries, robots or collaborative robots.